This page contains info of technical data to maintain and service your precious steed.

TDC: Muerto superior, верхней мертвой точки, Pointe morte haut, Oberer totpunkt, Morto superiore are some translations for top dead-centre.

BDC: Punto muerto inferiorare, Point morte inférieur, Unterer Totpunkt, are some translations for bottom dead-centre.

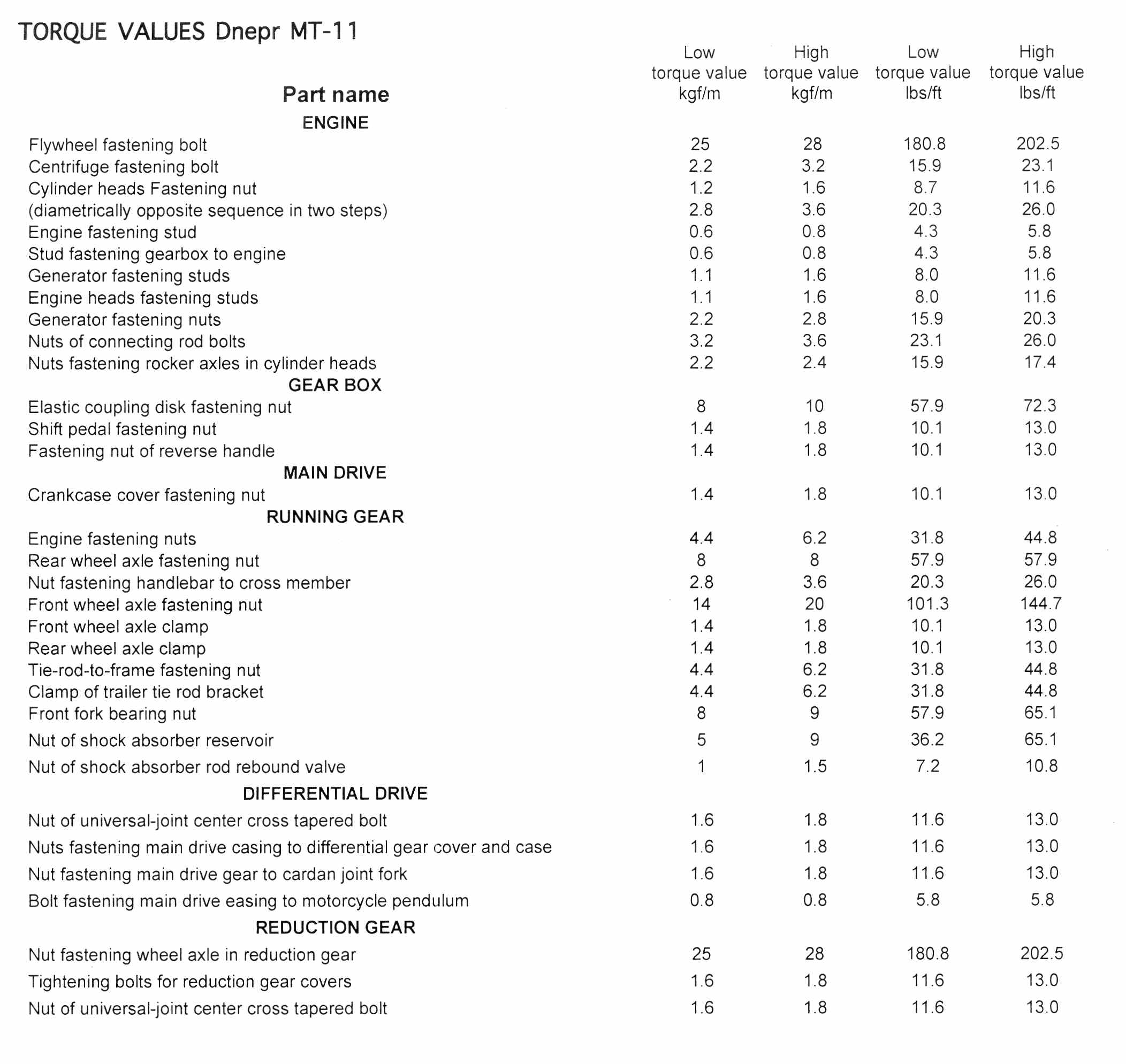

Torque Conversions

Kilogram-force Meter to Newton Meter

Kilogram-force Meter short kgfm and Newton Meter short Nm

1 kgfm is equal to 9.80665 Nm

Foot-Pounds Force to Newton Meter and the other way around

1 ft.lbs = 1.35 Nm, 1 Nm = 0.738 ft.lbs

| Torques values | M72 – K750 | |||

| part | thread | spanner-size | force Nm | force ft lbs |

| Cylinder heads bolts | 16* M10x1.5 | square 11 or hexagon 17 | 29-33 Nm | 21.4-24.4 ft. lbs |

| Flywheel/clutch screws | 6* M8x1x15 countersunk | 22-25 Nm | 16-18.5 ft. lbs | |

| Flywheel nut | M18x1 | hexagon 36 | 245-274 Nm | 180-202 ft. lbs |

| Cylinder base nuts | 4* M10x1 2* M8x1 | hexagon 17 hexagon 13 | 38-42 Nm 22-25 Nm | 28-30 ft. lbs 16-18.5 ft. lbs |

| Top pinch bolt, plunger | M8x1-70 | hexagon 13 | 21-30 NM | 16-22 ft. lbs |

| Bottom pinch bolt, plunger | M8x1-70 special bolt 7209448 | hexagon 13 | 36-50 Nm | 26.5-37 ft. lbs |

| Bearing nut | 30-34 Nm | 22-25 ft. lbs | ||

| Oil pump bolts | 2* M6x1-60 | hexagon 10 | 16-18 Nm | 12-14 ft. lbs |

| Engine sump | 12*M6x1-18-25 depending on type sump | hexagon 10 | 8-10 Nm | 6-7.5 ft. lbs |

| Distribution cover screws | 6*M6x1-40 4*M6x1-30 | countersunk screw | ||

| Final drive case nuts | 6*M8x1 | hexagon 13 | 14-18 Nm | 10-13 ft. lbs |

| Crown wheel bolts | 8*M8x1.25 | hexagon 13 | ||

| Pinion bearing nut Cardan cap | M56x1.5 left M58x1.5 left | hook wrench | 7-9 Nm | 5-7 ft. lbs |

| Prop shaft wedge | M8x1 crown nut | hexagon 13 | ||

| Reverse gear lever nut | M8x1 | hexagon 13 | 22-28 Nm | 16-21 ft. lbs |

| Steering head nut | M36 | hexagon 36 | 14-16 Nm | 10-12 ft. lbs |

| Sidecar wheel nut | M20 x 1.5 | hexagon 24 | ||

| Sidecar eye-bolts | M12x1.25 | hexagon 19 |

From German site :

Drehmoment Zylinderkopfschrauben drei Durchgänge über kreuz von innen nach außen

Erster Durchgang 15 Nm

Zweiter Durchgang 25Nm

Dritter Durchgang 33Nm

Tightening torques

Tightening torques for threaded connections in Newton meter.

Friction coefficient for steel: 0.14 (new, non-lubricated).

Friction coefficient for stainless steel: 0.12 (new, clean and undamaged).

If you use grease in any way or even Loctite, the friction will be less so the torque should be less too!!

This is a list to guide you if you don’t know the precise value. Use the manufacturer data if you have that, they know best !! Be aware that a steel bolt in aluminum needs less torque ! Often in a old casing the thread is damaged/gone by bolts that were too fastened!

Use of this guide is for own risk, we don’t take any responsibility for use of it !

| Steel 4.6 | Steel 5.6 | Steel 6.9 | Steel 8.8 | Steel 10.9 | Steel 12.9 | Stainless 50 | Stainless 60 | Stainless 80 | |

| Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| M4 | 1.0 | 1.3 | 2.6 | 3.0 | 4.3 | 5.1 | 1.3 | 2.6 | 3.5 |

| M5 | 1.9 | 2.6 | 5.1 | 6 | 8.5 | 10.2 | 1.8 | 3.8 | 5.1 |

| M6 | 3.4 | 4.5 | 8.7 | 10.3 | 14.7 | 17.7 | 3.1 | 6.7 | 9.1 |

| M8 | 8.2 | 10.8 | 21.6 | 25.4 | 35.3 | 42.2 | 7.6 | 16.3 | 21.7 |

| M10 | 16.7 | 21.6 | 42.2 | 50 | 70.6 | 85.3 | 15.4 | 33 | 44 |

| M12 | 28.4 | 38.2 | 73.6 | 87.3 | 123 | 147 | 26 | 56 | 74 |

| M14 | 45.1 | 60.8 | 117 | 138 | 194 | 235 | 42 | 89 | 119 |

| M16 | 69.6 | 93.2 | 179 | 211 | 299 | 358 | 63 | 136 | 181 |

| M18 | 95.1 | 128 | 245 | 289 | 412 | 490 | 91 | 196 | 261 |

| M20 | 135 | 180 | 384 | 412 | 579 | 696 | 128 | 274 | 366 |

| M22 | 182 | 245 | 471 | 559 | 785 | 941 | 174 | 206 | 494 |

| M24 | 231 | 309 | 598 | 711 | 1000 | 1196 | 222 | 264 | 634 |

| M27 | 343 | 461 | 888 | 1049 | 1481 | 1775 |

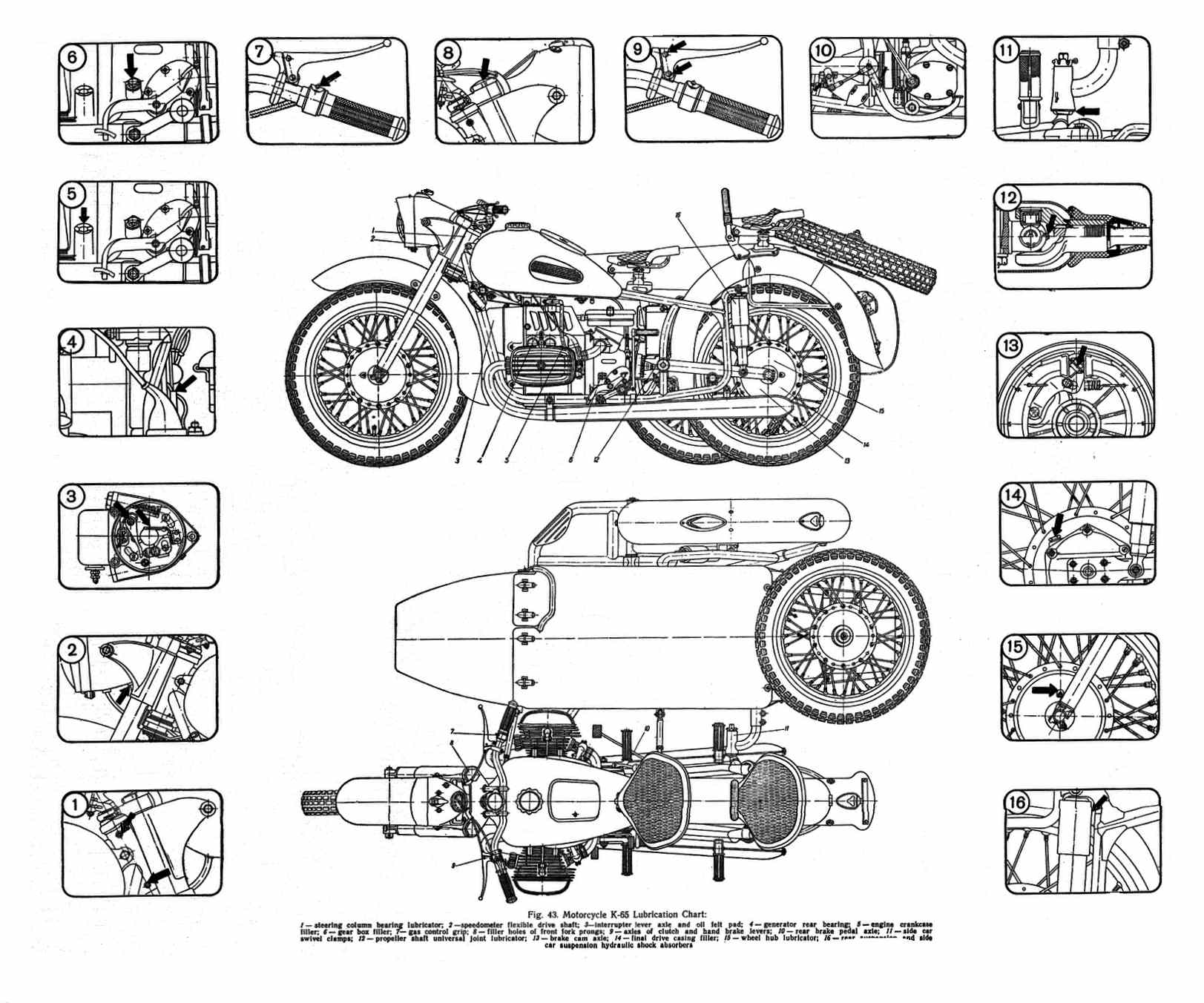

k-650-lubrication

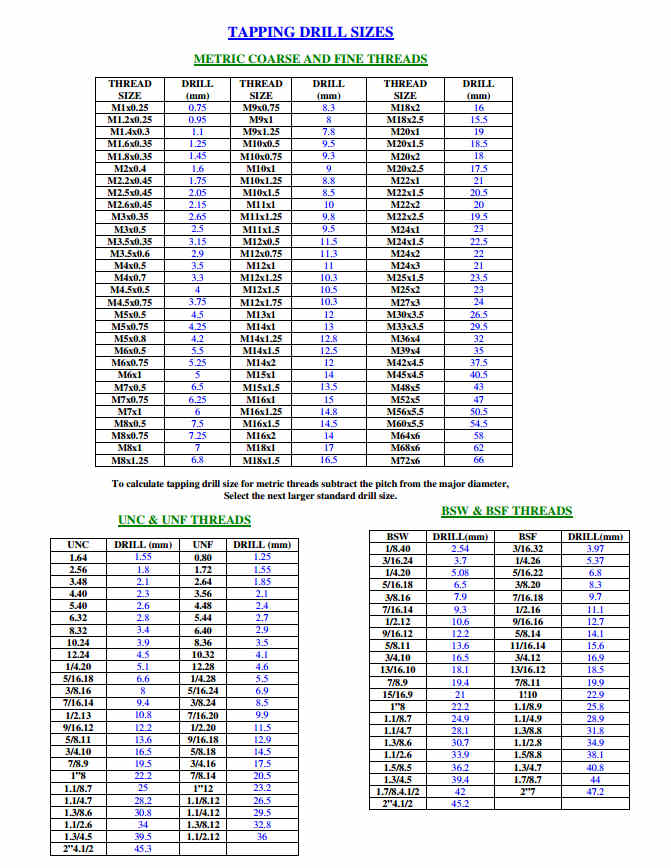

Thread-drill sizes

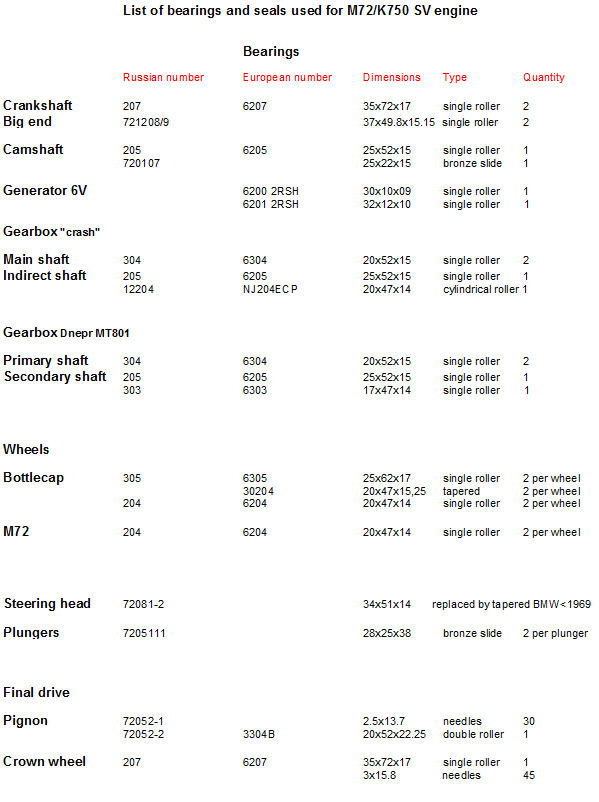

list of bearings

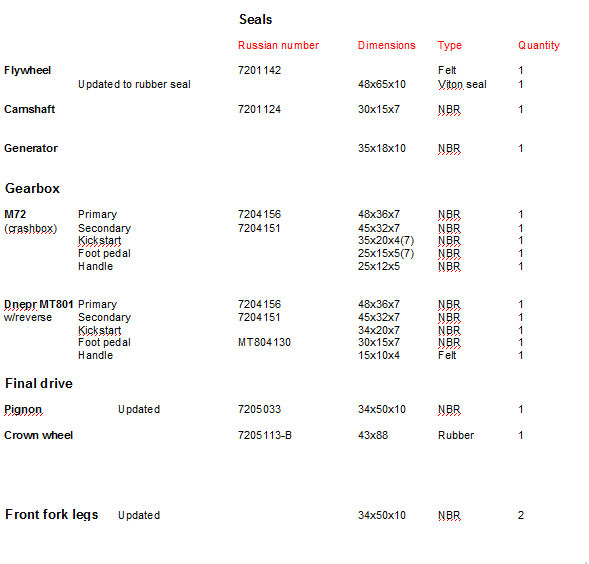

list of seals