On this page we look at “Motor Spirits” and various other useful information about fuels

Petrol, gasoline, fuel, in many languages, the name of the highly inflammable product is derived from benzene, such as Benzin in Persian (Persian: بنزین), Turkish and German, benzina in Italian, or bensin in Indonesian; in Argentina, Uruguay, and Paraguay, the colloquial name nafta is derived from that of the chemical naphtha. In Russia it’s бензин (Benzin).

Introduction

Kerosene.

Kerosene, or kerosine, also known as parrafin, is a combustible hydrocarbon liquid which is derived from petroleum. It is widely used as a fuel in aviation to power jet engines (jet fuel), even rockets and as carbon oil has been used for lighting and heating for millenium.

First made by oil-from-coal (or oil shale) processes, the illiminating oil industry switched completeley to petroleum from around the 1860s.

As kerosene production increased, whaling declined. Electric lighting started displacing kerosene as an illuminant in the late 19th century.

In the early to mid-20th century, kerosene or tractor vaporising oil (TVO) was used as a cheap fuel for tractors and hit ‘n miss engines The engine would start on petrol, then switch over to kerosene once the engine warmed up. On some engines a heat valve on the manifold would route the exhaust gases around the intake pipe, heating the kerosene to the point where it was vaporized and could be ignited by an electric spark.

The rise of the petrol-powered automobile in the early 20th century created a demand for lighter hydrocarbon fractions, and refiners invented methods to increase the output of petrol, while decreasing the output of kerosene. In addition, some of the heavier hydrocarbons that previously went into kerosene were incorporated into diesel fuel.

In Europe following the Second World War, many automobiles were modified to run on kerosene rather than gasoline. Besides additional piping and the switch between fuels, the head gasket was often replaced by a much thicker one to diminish the compression ratio (making the engine less powerful and less efficient, but able to run on kerosene). The necessary equipment was sold under the trademark “Econom”.

Kerosene is sometimes used as an additive in diesel fuel to prevent gelling or waxing in cold temperatures.

Ingestion of kerosene is harmful, even fatal. All fuels should be respected for their strong vapours and imflammability (explosiveness).

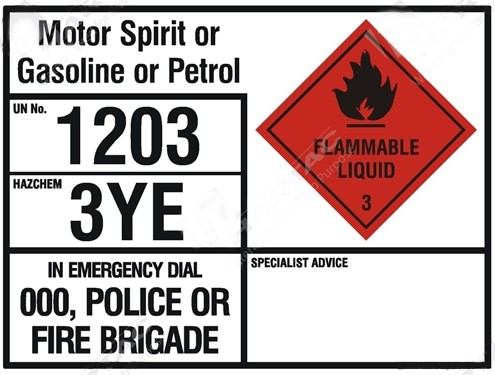

Motor Spirit.

British refiners originally used “motor spirit” as a generic name for automotive fuel and “aviation spirit” for aviation fuel (Avgas). The term “Motor Spirit” made its way into laws and regulations, so the term remains in use as a formal name for petrol. For example, a fuel tanker will deliver “20,000 liters of Premium Motor Spirit” to a service station.

A guide to storing fuel.

Fuels are manufactured to rigorous quality guidelines. In addition, the fuel in the underground tanks at petrol stations is replenished regularly so storage problems rarely occur. However, in smaller storage containers such as vehicle fuel tanks and drums, storage problems may occur. This information will help you maintain the quality of fuels stored away from the petrol station.

For domestic use, fuel should be stored in steel cans of 2.5 litres up to 20-25 litre jerry cans. In Australia plastic containers of the approved type with the Australian Standards mark (AS2906-1991) on the bottom can also be used. For plastic fuel containers in other countries please do your own research on fuel containers. Please note that the storage of fuel in any quantity is hazardous and this information does not include safety and legislative guidelines for fuel storage. In Australia for details on these safety and legislative guidelines for fuel storage please refer to the Australian Standard AS1940.

In general, Fresh fuel, will stay fresh for around 12 months. after that it will decay. For two-stroke fuel mixed fuel should be used within 30 days of being mixed to ensure the fuel is stable and combustible.

Petrol.

Petrol is a mixture of many components with different properties that contribute to the performance of the fuel. When petrol is kept in an open container where it is exposed to the air, it will – in time – completely evaporate. As it evaporates, the composition and properties will change because different components evaporate at different rates. This is a normal

feature of petrol and helps describe the process which takes place when it is stored in equipment fuel tanks, ie motorcycle and car fuel tanks.

Octane Rating.

In brief, it is possible for a fuel to have a Research Octane Number (RON) of more than 100, because iso-octane is not the most knock-resistant substance available. Racing fuels, avgas, LPG and alcohol fuels such as methanol may have octane ratings of 110 or significantly higher. Typical “octane booster” gasoline additives include MTBE, ETBE, isooctane and toluene. Lead in the form of tetraethyllead was once a common additive, but its use for fuels for road vehicles has been progressively phased out worldwide, beginning in the 1970s. Unleaded 91, 95 and 98 octane and E10 fuels are the current norm.

In the wars years (and for many years afterwards) equipment had to be able to run “on the smell of an oily rag” and low octane fuels were often the only fuel available. Most older Soviet bikes could run on 72 octane fuel.

Petrol in sealed containers.

The storage life of fresh petrol is one year when stored under shelter in a sealed container. Once a seal is broken the fuel has a storage life of six months at 20°C or three months at 30°C.

Petrol in equipment tanks (Your fuel tank).

The storage life of petrol in equipment fuel tanks is one month. This can be extended by topping up with one third of fresh fuel, which restores the volatile components that have evaporated.

Topping up with fresh fuel will help, however it is not a foolproof strategy for engines that are used only intermittently.

The following principles may also help:

Keep the tank half full to stop water vapour from being sucked in and condensing.

Consider using a premium fuel that contains anti-oxidants, metal deactivators and corrosion inhibitors to protect metal surfaces;

Use a hotter spark plug to help to reduce carbon deposits.

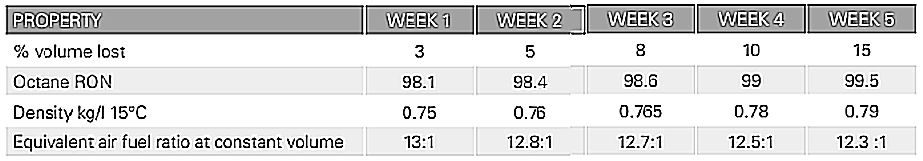

Example of how petrol changes when stored in a fuel tank

At the end of five weeks the fuel is 5% heavier and the fuel air mix will contain more fuel. This means your engine will run richer possibly resulting in fouled spark plugs and higher fuel consumption.

Petrol in boats (not motorcycles but will include this here for reference)

Petrol in boat engines exposes the fuel to conditions that are not normally encountered in cars or motorcycles, including lengthy storage and moisture.

Long term storage (Boats).

When preparing to store a boat for extended periods e.g. two months or more, it is best to completely remove all fuel from the tank. If it is difficult or not possible to remove the fuel, maintaining a full tank of fuel and including a fuel stabiliser to provide fuel stability and corrosion protection is recommended. A partially full tank is not recommended because the void space above the fuel allows air movement that can bring in water through condensation as the temperature cycles up and down. This condensation can potentially create operational problems.

The impact of fuel entering the crankcase.

Four-stroke petrol and Diesel engines

What happens when the fuel is not fully burned off in the combustion chamber? The answer to this question is also the cause of certain breakdowns, i.e. that the fuel tends to flow towards the crankcase. In fact, it flows down through the piston skirt towards the crankcase, where it mixes with the engine oil.

Once this anomaly happens, there are number of effects. One of these is the washing of the cylinder liner walls, the piston skirt and the segments, which implies that the fuel wipes away the oil lubricating the cylinder walls, leaving the area without lubrication and the cylinder liner walls polished.

Although this may sound like everything has been given a great clean, nothing could be further from the truth: in reality, the lack of lubricant means that the surfaces rub against each other, which causes wear. When polished, it is more difficult for the liner to keep the lubricant in the area, which can lead to faults such as the seizing up of the piston and damage of the cylinder bore itself.

Another effect of fuel leaking into the crankcase is oil dilution. This causes the lubricant to lose viscosity, meaning that the films formed are weaker and less capable of withstanding high loads that can occur at certain points, such as the critical rod bearings and crankshaft areas.

What happens if the viscosity becomes too low ? This causes contact between the metal surfaces, leading to rapid wear of the bearings due to friction.

A third effect of fuel passing through the crankcase is related to bio-fuel. Currently, both diesel fuel and gasoline include bio-fuels in their formula (biodiesel in the first case, and bio-ethanol in the second).

Diesel/Distillate.

Diesel is not an extremely volatile fuel therefore it does not suffer from starting issues or from the issues of evaporation that petrol does. The main issue with diesel fuel in storage is the formation of gums and sediments that can block filters. This is associated with darkening in the colour of the fuel. When stored under cover in sealed containers it will usually last for one year but it can last longer.

The main problem with diesel fuel in opened containers is that moisture from condensation will create a favourable environment for fungus and bacteria that degrade the fuel. The simple solution is regular treatment with a biocide every six months when storing for lengthy periods. (see further notes below)

As diesel fuel is subject to high temperatures in the crankcase, some of it evaporates, meaning that, in the case of diesel, the portion of biofuel becomes concentrated. This causes the biodiesel to be less fluid and more viscous than the diesel fuel, which causes the lubricant to thicken.

For example: a diesel fuel comprised of 7% biodiesel, the diesel fuel portion evaporates in the crankcase, meaning that the concentration of biofuel can amount to more than 10% of biodiesel. Due to this effect, the viscosity of the lubricant and fuel mixture increases, and the wear on the bearings can speed up significantly.

LPG storage.

LPG is not affected by the shelf life issues associated with petrols and diesels. It is stable

when stored in sealed containers.

Ethanol blends.

Regular unleaded with up to 10% ethanol has an equivalent storage life to regular petrol. As with regular petrol, when using an engine after a period of storage, always top up with a third of fresh fuel first. With ethanol blends, this will remove trace water and dry the system out as well as freshening up the old fuel.

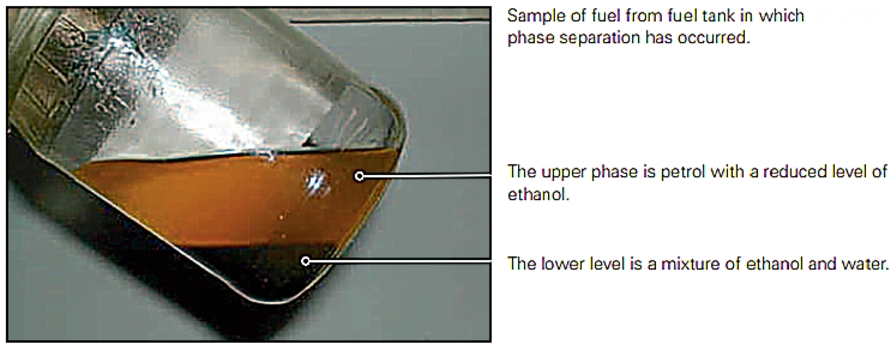

What is phase separation and how to deal with it? (Ethanol fuel only)

Phase separation is when water contaminates the fuel tank or fuel system causing the ethanol content to separate from the regular petrol.

The level at which phase separation can occur is determined by a number of variables, including the amount of ethanol, the composition of the fuel, the temperature of the environment and the presence of contaminants. It is very important that the system is inspected for significant quantities of water in the tank before using gasoline with ethanol and to limit exposure of the fuel tank to excess water. If phase separation has occurred, it is necessary to completely remove all free water from the system and replace with fresh fuel before continuing operation. Otherwise, engine problems could occur.

Upper Cylinder lubricant.

Upper cylinder lubricant is a highly refined mineral oil added to petrol in the applicable ratio recommended by the manufacturer. Brands include Firezone and Red-X. Regular use of an upper cylinder lubricant helps lubricate piston rings, cylinders, and valves, it can improve fuel consumption, and improves and equalizes compression.

Water/Alcohol mist induction.

This is a separate topic so just a brief summary. In rain on early mornings you may have noticed your fuel economy improves by a small amount? Could it be the higher water vapour content in the air? An old technique called water injection was used by Chevrolet in 1928 and in the world War 2 era. Basically a fine mist of (distilled) water (sometimes with a little methylated spirit / ethanol / alcohol) is introduced into the air intake manifold along with the fuel and this is burnt in the combustion chamber(s). The water mist is converted to steam which increases the compression ratio of the engine. The steam also cleans the build up carbon in the cylinders.

The needle valve used to control the flow of water into the intake manifold is critical in its percent open state: even just a little too much water and the engine will splutter so its very important to use the smallest possible flow of water to achieve misting.

One Ural dealer in the 1980s offered a water mist induction option. A standard Soviet float bowl complete with tickler was fitted to a small tank along with an On/Off valve tap. The tap had to be in the OFF position to start the bike and when riding around town as the bike would stall at traffic lights or even cut out if you slowed down. But I have to comment from personal experience as a test rider, out on the highway, turn the tap ON and it was like putting your foot down on a V8. The motor instantly cooled down and ran much quieter.

Nitrous Oxide.

Watch Mad Max2 or go to the drag races! Nuff said?

Fuel injection.

The carburettor became a thing of the past. Modern day Urals use fuel injecion as do almost all modern vehicles.

Lastly, for the die-hards and millions of IZHs, we will look at two-stroke petrol engines…

Two-stroke petrol engines.

Two-stroke oil (also referred to as two-cycle oil, 2-cycle oil, 2T oil, or 2-stroke oil) is a special type of motor oil intended for use in crankcase compression two-stroke engines. Once mixed it is generally referred to as petroil or premix or just two-stroke.

Soviet two-strokes are petroil mix ratio 25:1. That is you have to pre-mix the 2-stroke oil with the fuel (unless you have a rare Sport model that has a separate oil tank)

When two stroke fuel is mixed correctly it has similar storage requirements as petrol. Problems arise when excessive two stroke oil is added. Under this condition the oil may separate from the fuel, not to mention a smokey exhaust!

For two-stroke fuel mixed fuel should be used within 30 days of being mixed to ensure the fuel is stable and combustible.

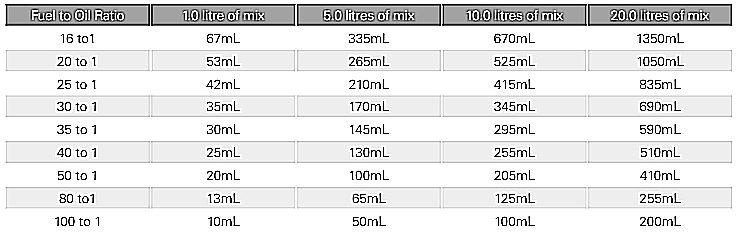

Running in a NEW two-stroke engine.

The table below is for mixing two stroke volumes and determining oil quantities on a NEW two-stroke engine during its running in period. It shows the amount of oil in ml required for 1.0 litre, 5.0 litres and 20.0 litres of fuel etc. Always refer to the owner’s manual for correct fuel to oil ratio for your engine.

The table below is useful for mixing two stroke volumes and determining oil quantities in a run in two-stroke engine with a 25:1 ratio mix…

How to mix two-stroke petrol with 25:1 ratio of fuel to 2-stroke oil:

Using EXACTLY the right amount of two-stroke oil to your fuel mix is ESSENTIAL!

so to clarify: for ratio 25:1

- 1 litre 40ml

- 2 litres 80ml

- 2.5 litres 100ml

- 3 litres 125ml

- 4 litres 160ml

- 5 litres 200ml

- 10 litres 400ml

- 20 litres 800ml

and so on. It sounds like you need laboratory equipment, but it’s as easy as a lawnmower. An easy to read measuring vessel is all that’s needed, plus a sharp eye to get accurate measurements.

Too much oil will foul your spark plug. too little oil will seize your motor!

IMPORTANT! Remember, for 2-strokes:

Using EXACTLY the right amount of two-stroke oil to your fuel mix is ESSENTIAL!

Always start by filling half the amount of the petrol to be used. Then add the entire amount of two-stroke oil. Then mix (shake) the fuel mixture, and then add the remaining amount of petrol, and shake again. This will prevent the oil mixing outside of solution.

Notes:

Give your 2-stroke bike a bit of a shake before starting to keep the fuel mixed.

If your carburettor/s have a mesh filter bowl (water trap) it is highly recommended to clean the trap regularly, i.e. weekly or monthly.

Once upon a time there was BP Zoom25 which was a popular 25:1 two-stoke premix, straight from the petrol pump, most BP service stations had a Zoom bowser, usually around the side of the building to prevent motorists pumping it into their cars. I don’t know if it’s still available these days, probably not, it was a convenient way to fill a tin for your lawnmower or ride up and refuel your Voskhod, but it was cheaper to mix the petroil yourself.

I hope this information is useful.

compiled by JD

former Petroleum transfer engineer, Voskhod and Jupiter owner

other sources:

Motor Vehicle Craft Studies 380 – Principles – FK Sully – Butterworths

Cossack Owners Club UK

British Petroleum 2-stroke Guide

Total

Shell.com