The “clearance or gap” should be adjusted on the “cold” engine.

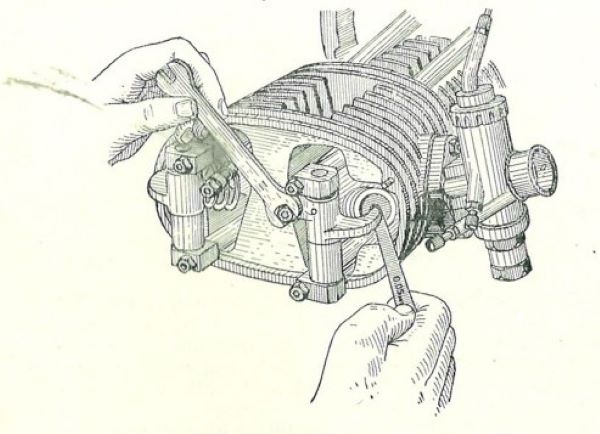

Tip for SV engines: use some old 14 mm spanners where you cut off a bit from the “head” to have more working space 🙂

I don’t know about the space on OHV engines !

Removing of sparkplugs, not really needed but engine turns much easier !

Method from manual. Turn engine till inlet valve closes, now you can set clearance for exhaust valve 0.15

Then continue to turn the engine crankshaft, until the exhaust valve starts to lift and set clearance for inlet valve 0.10

This is the short version, see: adjustment of valves on Dnepr K-650 and MT-9 for the extensive version, only use different values for clearance 🙂

Method BMW. Turn engine till one of the sides the valves are “tumbling” at TDC. Now you can check/set the clearance on the opposite side, both valves ! Turn engine further till TDC again and valves on other side are “tumbling ” check/set the valve clearance on opposite side. Clearance: inlet valve 0.10 and outlet valve 0.15

If you don’t have a kickstart, set the motor in 4th gear and turn with the wheel.

M72, K750

Set exhaust valve clearance to 0.15mm.

Set inlet valve clearance to 0.10mm.

DNEPR K-650/MT-9

Adjustment of valves on Dnepr K-650 and MT-9

Set valve clearance expansion gap to 0.07mm on all valves on a COLD engine.

(Tip: you could use a 0.05mm and 0.02mm feeler gauge together = 0.07mm)

Procedure:

- 1. Remove the spark plugs (makes turning the engine easier). Place oil tray under both cylinders and remove rocker covers.

- 2. Using the kickstarter very slowly turn the engine crankshaft until the inlet valve closes (a certain clearance between the inlet valve stem and the rocker end face must be well felt, and you must be able to spin the pushrod end with your fingers).

- 3. In this position adjust the exhaust valve clearance to 0.07mm. Following that, tighten up locking nut.

- 4. Then continue to turn the engine crankshaft slowly until the exhaust valve starts to lift and set the inlet valve clearance to 0.07mm. Following that, tighten up locking nut.

- Repeat the above procedures on the opposite cylinder head.

- Return to the first cylinder set and repeat Steps 1,2 and 3, checking the gaps on both exhaust and inlet valves, ensuring gaps of 0.07mm. Readjust if necessary. Following that, tighten up locking nut.

- Return to the second cylinder and repeat Steps 1,2 and 3, checking the gaps on both exhaust and inlet valves, ensuring gaps of 0.07mm. Readjust if necessary. Following that, tighten up locking nut.

- Repeat once again (3rd time around) ensuring gaps of 0.07mm on all valves. Repeat again if necessary. Following that, tighten up locking nut

Tip: If you keep getting incorrect readings check for a bent pushrod, damaged tappet end face or bush, or damaged cam follower. Make sure small valve caps are undamaged and in installed in place.

MT-10/MT-11

Valve Adjustment

Set the piston to the top dead centre of compression stroke by turning the crankshaft so that mark “B” on the flywheel is in line with the mark on the engine crankcase.

In this position, both (inlet and exhaust) valves will be fully closed and their rocker arms must freely swing on their pins.

Then, using a 0.07mm thick flat feeler guage, check the clearance between both rockers and valves.

URAL M-62, M-63, M-66, M-67

Turn the crankshaft using the kick lever. Just when the intake valve begins to close, set the clearance for the exhaust valve and at the time the exhaust valve begins to open, set the clearance for the intake valve. Clearance 0.05 mm

750cc URAL 2002

The gap between valve stem and pushing arm of the rocker should be between 0.1…0.15 mm.