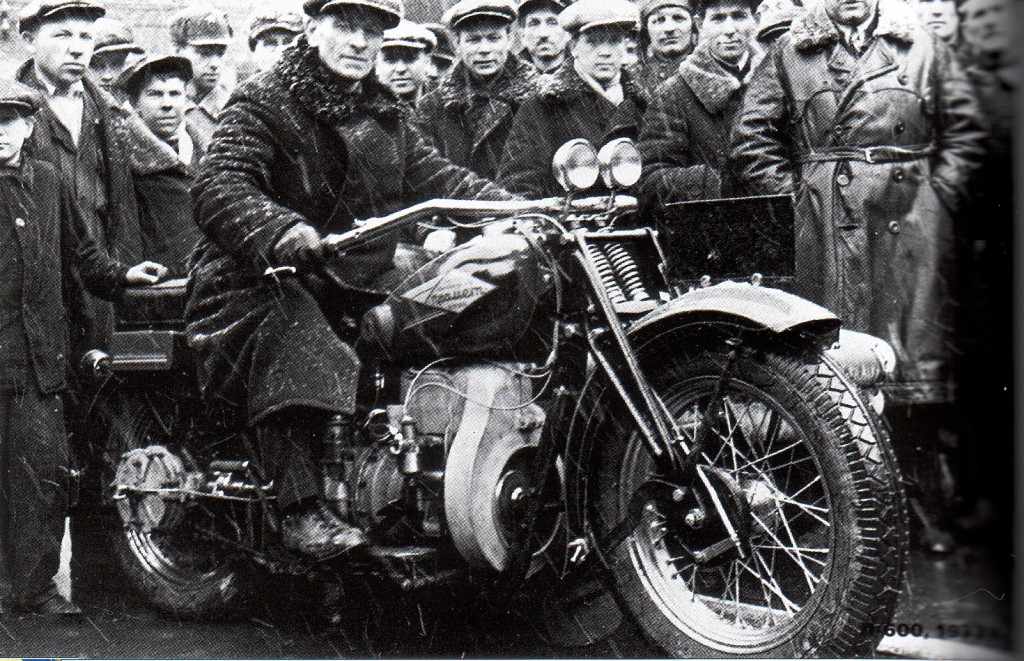

Letter L (Rus. Л ) meant different motorcycles built at several plants in Leningrad USSR in the 1930′s. It all started in 1929 when a team of designers headed by Pyotr Mozharov working on experimental motorcycles in Izhevsk was transferred to Leningrad to set about the mass production of motorcycle machines. But instead of beginning to mass produce experimental machines the team of specialists was given down an order to prepare a mass series copy of the German “DKW 300 Luxus”, which had a frame made of press-formed elements, springer front fork, made with the same method, two-stroke engine of 293cc, 3-speed gearbox and flywheel magdyno (transl. note: magneto+dynamo (or generator+electric starter as it was with Tula motorollers), two functions combined in one) and clincher type wheels. Mass production was ordered to be done by the Trust of mass machine building (Rus. contraction “Tremass”), which put this order on one of its submerged factories named “Promet”. The first series of the motorcycles was assembled in 1930, by much part a precise copy of the German model, the new L-300 (L – made in Leningrad; 300 – rounded engine capacity) and engine of smaller power output, 6.5 hp as its compression ratio was decreased for the engine to work on a fair quality petrol.

L-300 (Л-300) plackard front view.

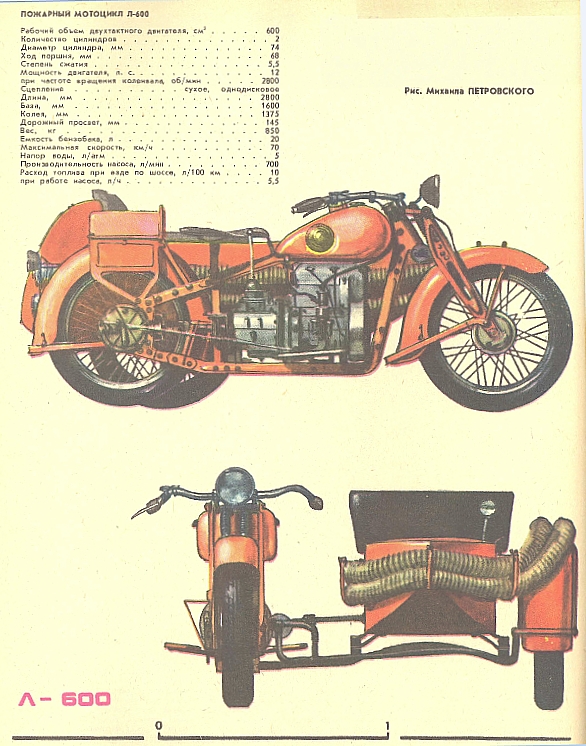

As production capacities of the Promet factory were not suitable for mass production of motorcycles, as it was supposed to, and in 1932 the production of the motorcycles was transferred to “Red October” factory that had much better equipment. But the Promet factory kept on working in motorcycle industry issuing different machines and mechanisms, including mechanical water pumps for fire fighters. Idea of mobile water pump was embodied in a unique motorcycle which was built in small series since 1934 under name “L-600″. A two-stroke twin cylinder engine of 600cc, 12 hp was set parallel into frame made of press-formed steel elements, similar to that of L-300 but much bigger in size. As the engine was not only to move the motorcycle but also to drive water pump 600 liters/minute productivity, a good cooling system was needed with cylinders placed one after another. To achieve this engine’s flywheel was place in front out of engine mounted to crankshaft axis end. Inside the flywheel there was a flywheel magdyno, outside – a big fan, covered with a casing it directed air to cool cylinders. Motopump with hoses and other equipment was placed in the sidecar, which was mounted on the left side of the motorcycle, driven by an auxilliary cardan shaft, while rear wheel of the machine was driven by main cardan shaft. The machines were made till the beginning of the Great patriotic war and were serving in many fire fighting brigades, often as the only means of fire emergency response.

L-600 (Л-600) fire fighting appliance

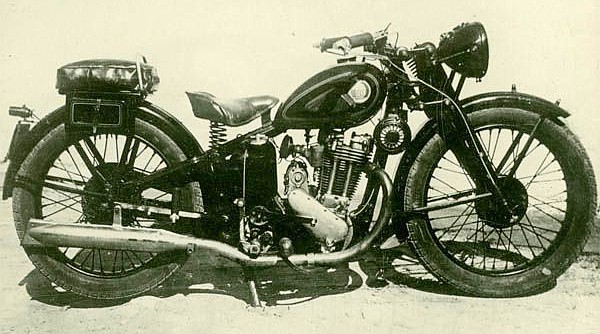

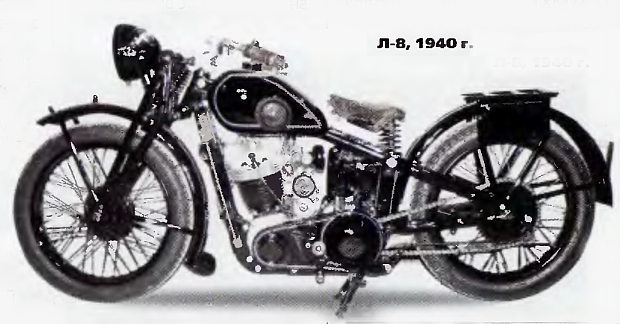

In 1934 staff of the Red October plant developed and built and experimental sample named L-500, which resembled L-300 in undercarriage design that its frame was made of press-formed pieces and had springer front fork, but the engine was completely different in its principles. It was an overhead English design with vertical cylinder and cylinder valve pusher drive, 45 degrees to horizontal line, dry sump engine system, 496cc , 18 hp. electric equipment included separate generator and magneto of ignition system. three speed gearbox had a hand lever shifter and was chain driven. Main drive was also chain with both wheels made interchangeable. Mass production was not commenced due to economic reasons: production site could not have afforded issuing two different models at the same time. Another possible reason was that Taganrog instrumental plant (“TIZ”) began to develop a heavy single cylinder motorcycle on its own, this work was planned and given necessary financing. By autumn 1935 another experimental model was ready L-350. It was an improved two-stroke 346cc, 10.5 hp improved mass-made machine of the factory, undercarriage remained the same (the factory designers minded adopting production of a new frame) but the engine was re-worked. Cylinder became vertical placed instead of tilted previously, piston with deflector was unchanged, though scavenging scheme differed that resulted in appearance of two exhaust pipes with silencers. L-350 remained in experimental samples possibly because a radically new machine was required and that power growth compared to L-300 was insignificant. Then factory designers decided to use maximum their experience of developed L-500 for a new mass-made machine, a first country’s overhead valve motorcycle, production of which was set at several factories. It had tilted cylinder engine with 348cc and developed 13.5 hp, dry sump crankcase, the cylinder made of cast iron, while casing and cylinder head of aluminum alloy, valve mechanism was oiled under pressure with special oil channel. First in the history of domestic motorcycle building a carburetor with horizontal throttle casing was used, electric equipment included magdyno of English type, used at that time on TIZ AM-600 motorcycles, the frame was made longer but left similar to L-300, 3-speed gearbox was also changed only in that its ratios were adjusted for more powerful engine. Clutch mechansim was altered as previous could not withstand bigger torque. Initially planned to be used with straight side wall tires and foot speed switch, in fact wheels remained clinchers and foot switch was a pedal in place of gearbox hand lever. It was difficult to use and most part of named L-8 series (Rus. Л-8) was equipped with hand gearshift lever. Experiments lasted for several years, though probe series were made since 1938, mass production of L-8 started in 1940, later at Serpukhov motorcycle plant (SMZ) and Izhevsk motoplant (IzhMZ). Izhevsk plant changed frame design and its machine had model name IZH-12, few of these were made.

L-8 (Rus. Л-8)

Motorcycles L-300 and L-8 were sold to general public and supplied to the Red Army. L-8 especially was used for competitions by many sportsmen of primary bodies of OSOAVIAKHIM (predecessor of DOSAAF and then ROSTO (voluntary/semi-voluntary sports and military orientation organization). For competition factory specialists made a special lightened version of motorcycle based on L-8 named C-1 (S-1) with 24 hp engine. Although to supply the army at that time with newly forming mechanized units and as means of transport many motorcycles with sidecars were required. To fulfill this a number of factories had to be re-equipped, this included “Red October’s” motorcycle division renamed LMZ – Leningrad motorcycle plant, (Rus. ЛМЗ). Continuing mass production of L-300, the factory was preparing for production of copy of german BMW R71, received by our country as a part of technical assistance and named M-72. Before the war began Leningrad made series of L-8, in July 1941 the factory was evacuated to Gorky town, on site of tools making workshop “Red Ethna”. In August same year the production began but the factory was dismounted and handed to GAZ for production of tanks. When in october 1941 Red Ethna received evacuated Kharkov motoplant (KhMZ) , industrial equipment of LMZ was given back from GAZ to enforce production capacities. Here motorcycle history of Leningrad machines ends.

All assembled motorcycles M-72 in Gorky were then counted for GMZ (Gorky motoplant).

It is interesting that “the Red October” returned to motorcycle theme adopting production of two stroke engines for engined bicycles and mopeds, widely known as “Deshka” (these engines had official name as “D” series), Last was D-20 engine model, which in 1997 was installed into experimental mokick (moped+kickstarter) “Fora” made at Latvian “Sarkana Zvagzne” factory. There were rumors that the machines would be made in St. Petersburg, but the model never got off conveyor.

Translation © by Eugene Radchenko, specially for b-cozz.com (June 2014)

Sources of information:

- Russian Encyclopedia of Motorcycles

- MOTO Moscow Russia

- Complete History of Soviet Motorcycles

- V/O Avtoexport USSR

- Steve Wiggins