Dnepr Logo

(KMZ, Kievskiy Mototsikletniy Zavod) Kiev motorcycle plant began to function soon after the capital city of Ukraine was cleared from German fascists’ occupation during the Great Patriotic War. For base of production Armoured Vehicles Repairing Workshops were utilized founded in 1932. Later it was renamed Armoured Vehicle Repairing Base, evacuated from the site in July 1941. After Kiev was regained at the end of 1943 the factory was reformed as 8th Armoured Vehicles and Tank Repairing Plant returned to its pre-war location with all its staff and equipment to repair soviet and captured military vehicles and assemble imported motorcycles supplied by Lend-Lease to the Red Army.

Dnepr plant

On 26 September 1945 was founded “Kiev motorcycle factory”. ….. In 1946 the first Kievlyanin was produced …..

The Kiev motorcycle plant was established on the basis of the Resolution of the Council of People’s Commissars of the USSR No. 2435-652 / C of September 21, 1945 and the order of the People’s Commissar of Medium Engineering of the USSR for No. 362 / C of 26 September 1945 on the basis of the former Armored Repair Plant № 8 in Shevchenkivskyi district of the city of Kiev along Kagatnaya street, 8 at present the street of the Khokhlov family.

Auto-armored workshops became the basis and the basis for the creation of the Kiev motorcycle plant. In 1932, on the territory and in the production buildings of KMZ factory, there were auto-armored workshops of the Kiev Military District. From October 1945 until the end of March 1953, the plant was subordinated to the General Directorate of the motorcycle and bicycle industry (Glavmotoveloprom).

In 1946 the first model of the two-wheeled motorcycle “Kievlyanin” K-1B, was made according to the documentation and on the equipment received by reparation from Germany, “Wanderer-1SP” (Wanderer). Initially, the engine for the Kiev plant was received by cooperation, but by in 1947 the plant began serial production of K-1B motorcycles with a motor of its own production.

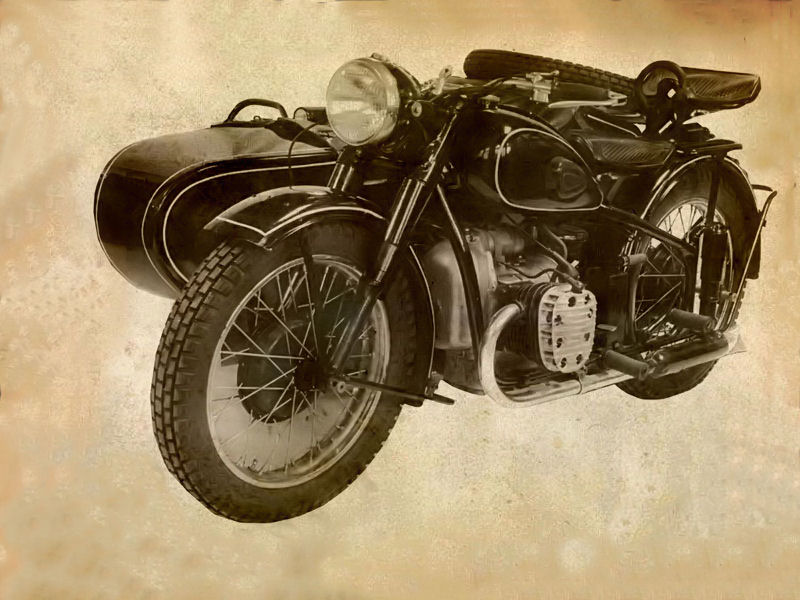

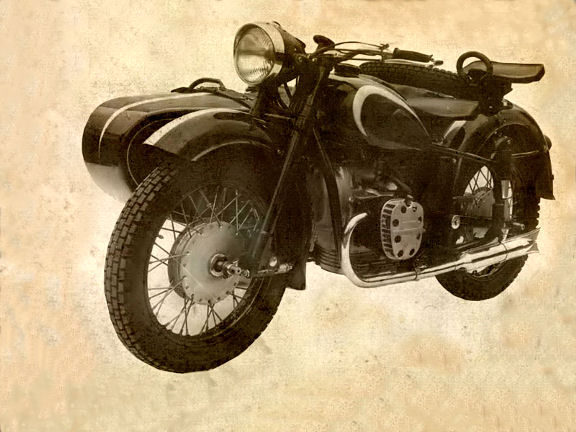

At the end of 1946, on the basis of the K-1B already in production, the first Soviet wheelchair for invalids K-1V began to be manufactured. Since 1947, the development of K-1V three-wheeled motorcycle began, the company had begun work on the construction of production shops and structures of the foundry and procurement shops. In 1949, 100 specialists from the liquidated Gorky motorcycle plant came to the plant, in preparations for the production of heavy-duty motorcycles M-72 began. Since 1956, the plant has developed and began to produce a new, more advanced model of the K-750. For the period from 1955 to 1970, motorcycle production was 45-50 thousand units per year.

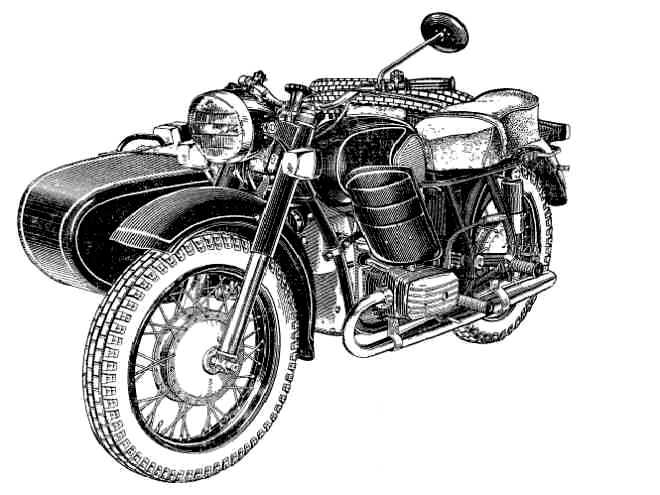

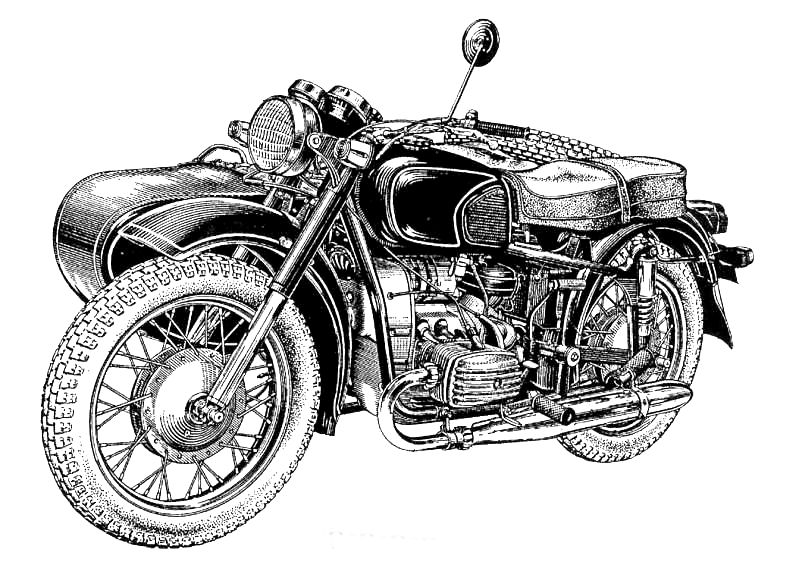

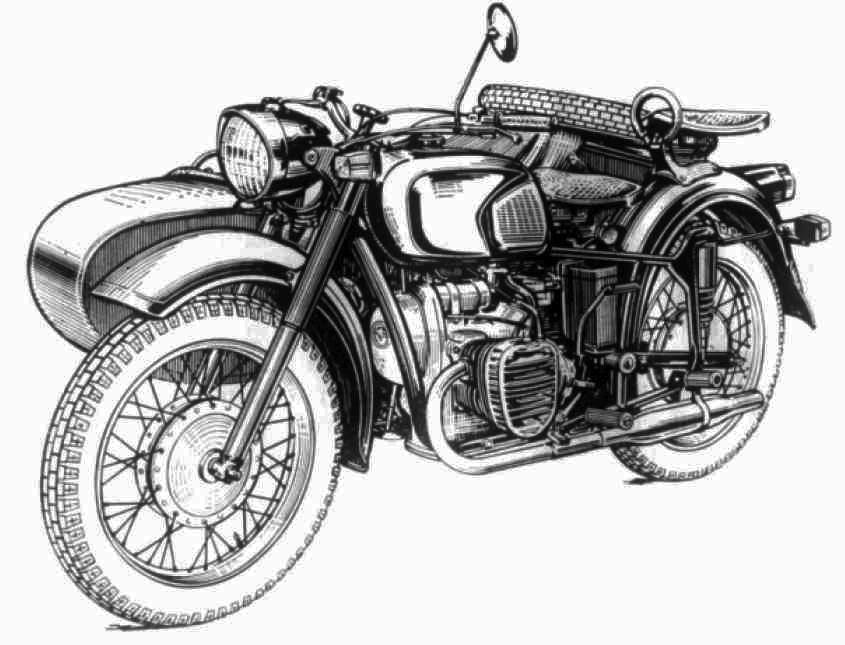

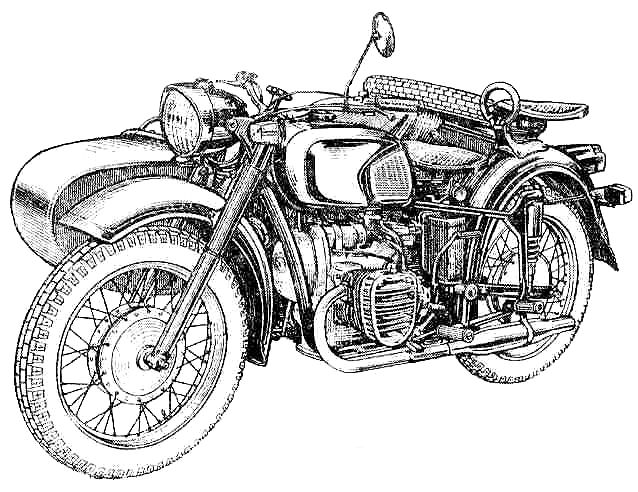

Dnepr models

The history of the Dnepr starts up in the 1946, but not with a “flat twin”. The first motorbike produced was a little two-stroke 98 cc, the “ К1Б”, or “Kievlyanin” (a citizen of Kiev). This motorbike was the Russian version of the Wanderer “98″ (a German motorbike similar to a Sachs), but it was not a simple copy, the original drawings and tools of the Wanderer factory were taken by the Russians as compensation for war damages, therefore the “Kievlyanin” is not “like” the Wanderer, but is the German bike build in Russia. Anyway, it was a very simple motorbike: a two-stroke, 98 cc, 2.2 hp engine and 2-speed gearbox, 50 km/h, bicycle pedals, no rear suspension. The “Kievlyanin” was produced until 1951.

In 1947 based on this model a tricycle K-1V appeared. It was designed for veterans of the Great Patriotic war with disabilities. And a small series of cargo tricycle K-1G was produced for postal, commercial and in-factory transportation of cargo. The machine was not widely used, as its low power engine could not have taken a somewhat sufficient cargo load.

In 1949 after GMZ (Gorky motofactory) was closed, hundred of its former specialists and a set of technological machinery for production of M-72 (it proved well during the war) arrived at KMZ. Because of lack of production base, the factory switched to making the new machine gradually, while making a reserve of parts for the old model and closing its production.

Since 1952 the models K-1B and K-1V were only assembled from parts left in the factory’s reserve. Later production equipment for K-1V was handed over to Serpukhov town, where these machines were mass-made at SMZ (Serpukhov motofactory).

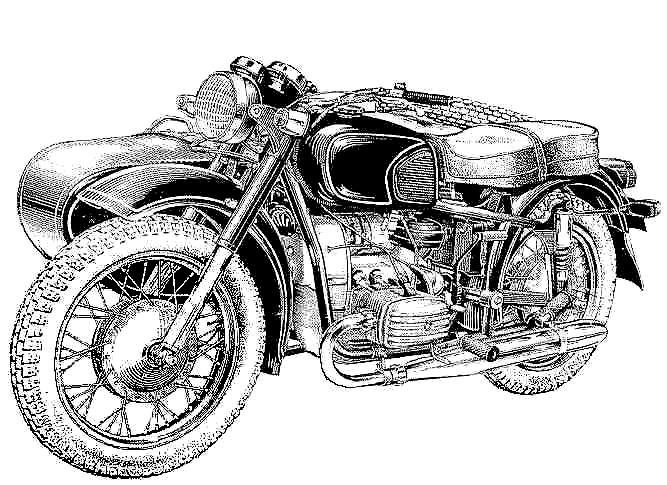

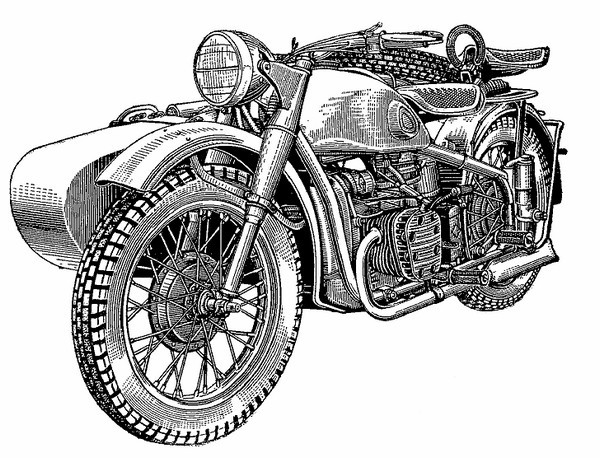

Since 1951, the KMZ-Dnepr begins the production of the “M-72″, totally similar to the Ural model that has the same name: flat-twin, 750 cc, side valves, 22 hp. Also an own Museum was realized, as typical feature of all the Soviet factories. In the 1971, the new generation with over-head valves Dnepr K-650 (with the longer head fins near carburetors) was launched, it was the base of the models currently produced.

In 1952 KMZ built 500 engines and gearboxes for M-72, while 500 kits of undercarriage parts were supplied by Irbit motofactory (IMZ). Following years co-operation with IMZ stopped gradually, as KMZ in its turn adopted its own production of undercarriage parts and assemblies in Kiev. At that period of time M-72 was aimed to be supplied for army, militia and other state services, so it was long produced without improvements in design.

After a governmental decree that afforded sale of the M-72s to private buyers was issued, the factory team run by main designer K.A. Pozdnaykov began work on the machine’s improvements. As a result, there appeared M-72H (English: M-72N, “new”), which, besides its improved finishing, received a modernized sidecar wheel suspension, enforced spokes of wheels and cast aluminium hubs. There were also many improvements in engine and transmission, but the main: a telescopic fork was replaced with a short-lever-type front fork and two rear hydraulic shock absorbers.

At the same time the factory was developing an experimental model M-53 and its sport modification M-53C (rus. ‘C’ stands for ‘sport’), the latter was a successful competitor in the USSR and other Socialist countries races. Unfortunately, the M-53 was not allowed for mass-production, but for 500cc OHV engine 26 hp, short lever front fork, pendulum rear suspension with angled shock absorbers, one-piece seat for rider and passenger were prevailing features over M-72. It has been referred to as perhaps the most beautiful motorcycle produced in the USSR, and also one of the rarest.

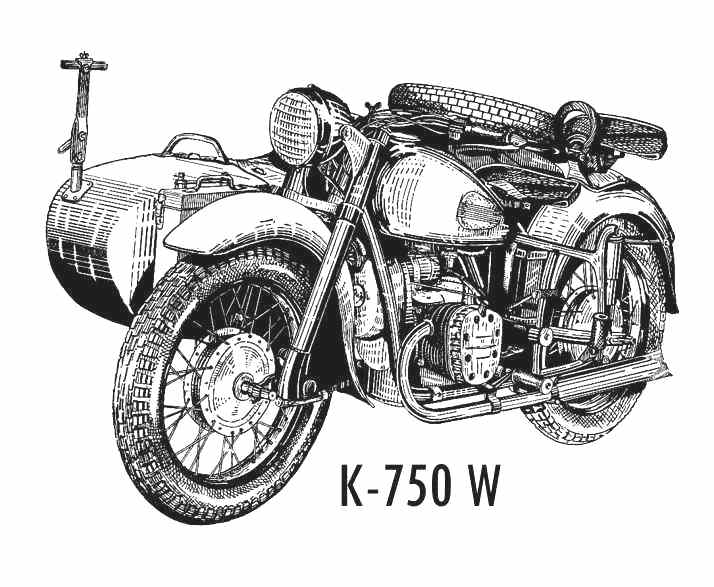

In 1958 a modernized machine production named “K-750” began. K-750 differed from the previous model radically: with increased compression ration engine power grew from 22 to 26 hp, improved engine cooling with finned oil sump, rear candle (plunger) suspension was changed for a pendulum (swinging arm) with both directions spring and hydraulic shock absorbers. The machines’ wheels could boast new cast aluminium hubs, equal-length spokes and adjustable taper roller bearings of the wheel hubs. A brake mechanism received balancer and wear compensator of brake shoes; sidecar body was mounted with rubber elements, sidecar wheel torsion design was replaced with both directions spring and hydraulic shock absorber suspension.

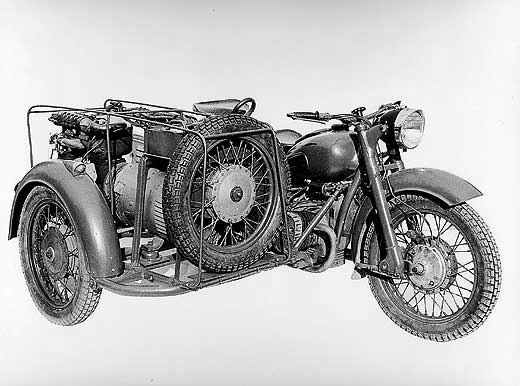

In 1960 as a part of KMZ experimental work a few four-wheel motoloaders were assembled: classical commercial vehicle design with plastic (some metal) cargo platforms and box carriers. Named “Kiev”, these machines had rail frame, independent front wheel suspension, and a K-750M engine with a cooling fan (by the way these engines were widely used in the Soviet army not only as stationary power plants, but as auxiliary engines on some of artillery units that were able to quickly change their position in combat, also railcars and other purpose-built units). Cargo load of the experimental cargo samples reached 600kg, but the machines were not mass made due to many reasons.

Also in 1960, the factory began work on developing a new type two-cylinder overhead valve (OHV) horizontally-opposed engine that would serve as a basis for a new generation of motorcycles.

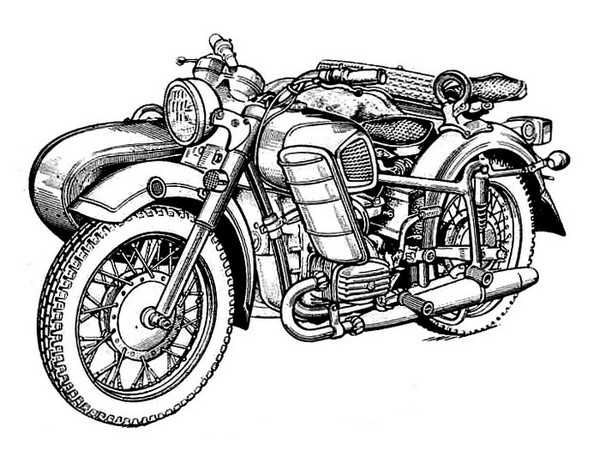

In 1964 a new improved model K-750M again had a telescopic front fork and rear had both directions spring and hydraulic shock absorbers, a similar off road version MB-750 was supplied for army with sidecar wheel drive. The drive consisted of two straight tooth gears without differential mechanism, drive shaft was mounted not inside sidecar frame tube (as on German war off-road motos), but near it. Worth noting is that M-750M engine had an increased service life due to improved cooling of cylinder heads and oil in a finned sump, to add a different gear shifting mechanism, brake drums insides got labyrinth sealing.

K-750CM

Based on main model a sports version K-750CM was created, it proved a successful racer on road and cross tracks. An important feature was unification of many parts and assemblies of Kiev and Irbit motorcycles, crucial for supplying motorcycle owners with spare parts.

In 1967 for 50th Anniversary of the Red Revolution the factory began to mass-produce motorcycle K-650 “Dnepr”, which main design feature was 649cc OHV engine, 32 hp. Attempting to increase service life of the engine a new design was applied: crankshaft bearings were new type – automotive type shell bushes, cylinders were cast of aluminum and press-fitted a cast iron sleeve. At the same time MB-650 having a sidecar wheel drive was supplied for the army.

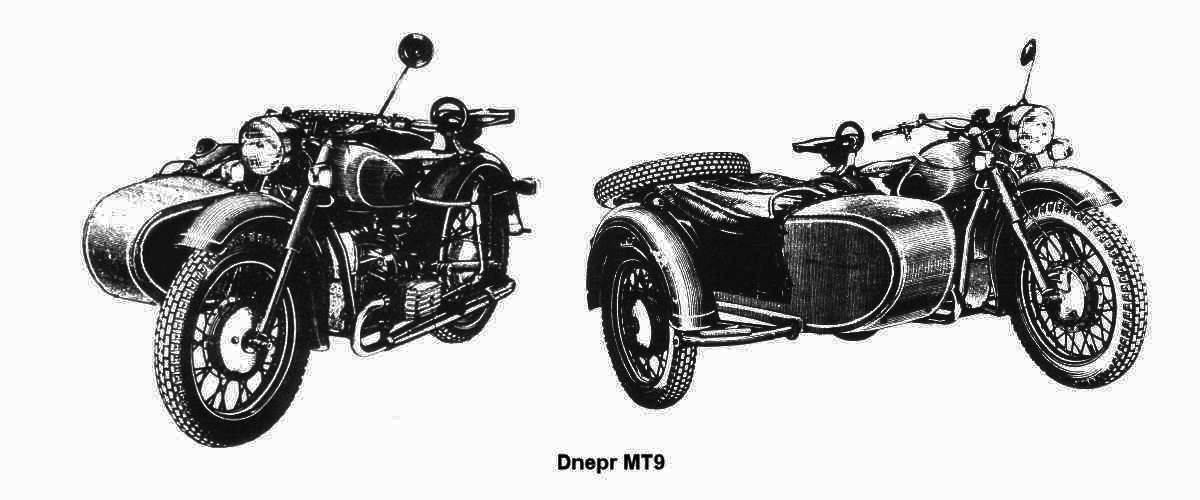

Later, when all-Union (GOST) state standards were changed, the model was named ‘”MT-8” produced till 1971, when it was succeeded by MT-9 with slightly modernized chassis and most crucial – a reverse gear was added. Namely “Dnepr” MT-9 became the 500000th machine produced by KMZ in November 1971 and was assembled at KMZ till 1976.

Year 1974 marked a new era for buyers: new model MT-10 could boast a 12 volt onboard electric system that greatly improved effectiveness of lighting and signaling. Unfortunately, these were the only improvements besides a double cushion for sidecar passenger and a new fuel tank of increased volume.

In 1976 the factory conveyor issued the first series of new model Dnepr MT-10-36 that with modernized carburetors had increased engine power from 32 to 36 hp. The following year buyers could evaluate MT-12, though under a new model name there was a disguised old but reliable sidevalve 750cc engine and transmission with sidecar wheel drive of MB-750 used with a new undercarriage

Same machine named MB-750M was supplied to the Red army since 1973. There is no proven information for reasons of MT-12 appearing for open market sale, it may have been army authorities that rejected this motorcycle and KMZ was forced to use parts in reserve, but maybe the factory was ordered to “open secret stuff” and let this military production for general public. Interestingly that the motorcycle for civil use was modernized with a gearbox from OHV engine version, having not only a reverse gear, but also *automatic declutching mechanism when shifting gears.

1977 saw a very interesting motorcycle for road races. Kiev specialists developed “SSh-500” with two-stroke, four cylinder 494cc engine borrowed form a cutter, which was liquid cooled and had power of 75 hp at 10000rpm. The machine was equipped with 8×10” wheels and took part in USSR championships with success.

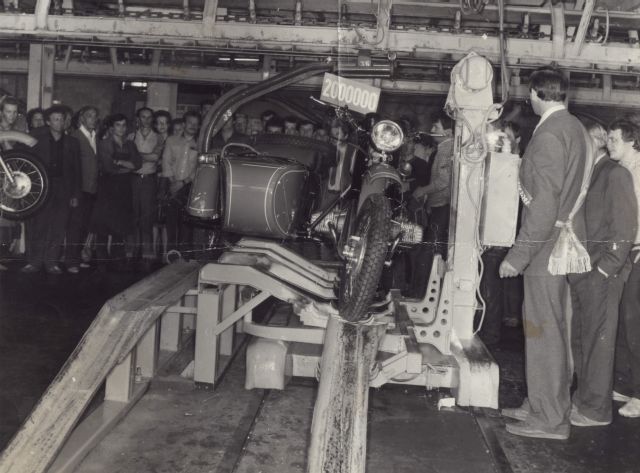

On January 26, 1979, from the factory gate left the millionth motorcycle – it was the “Dnepr” MT-10-36.

but then….. in 1989, one million motos in 10 years!

The two-millionth motorcycle from KMZ

Model “Dnepr” MT-10-36 was built till 1984 when it was changed with MT-11 having surprisingly engine of lower power, 32 hp instead of 36. A parking brake on the handlebar front brake lever, (probably an old idea from long ago), while other improvements were almost insufficient. Engine, gearbox and some other parts were made interchangeable with corresponding parts of motorcycles “Ural” of IMZ.

Two years later there appeared a version having MT 11 engine and sidecar wheel drive named MT-16.

After Ukraine became a fully independent state, motorcycles from Kiev were named “Dnipro” (prounounced “dneepoh”) and production output was decreased gradually. Since 1991 a solo motorcycle “Dnipro” KMZ 8.157.02 was assembled together with unchanged models “Dnipro” MT- 11 and MT-16 making the factory production line, sidecar versions were offered with telescopic front fork or long lever front fork.

By the year 2000 it was thought that the factory was closed, though it even continued working on experimental machines such as 1000cc engine motorcycle and cargo tricycle capable of carrying 600kgs of load.

KMZ were hoping to come out of stagnation and were planning to conquer a proper sector of the Russian and overseas markets. Several models were prepared to see if they were demanded by market. Sadly motorcycle and sidecar production at Kiev Motorcycle Works ceased.

Between the 1970s and 1980s, several prototypes of Dnepr powered by Wankel rotary engines were realized! These bikes, never entered in production, were engineered by the VNIIMotoprom (rus. ‘Technical Institute for the Motorcycle Industry Research’), in the city of Serpuchov, 70 km from Moscow.

Then the factory did research on a 4-stroke V-twin 750cc motorcycle resembling Italian make “Moto Guzzi” machines. Several such engines made at Serpukhov (VNII Motoprom) were mounted into a standard mass-series chassis of KMZ, but the progress did not go beyond experimental phase. Others were made with unique chassis.

The “RD-515″,, “RD-517″ and “Rotor V-500″, equipped with the same engine of the first prototype, but liquid cooled, with a power close to 50 hp, and a very strong torque at the mid-revolutions. The look is more modern, and there is some experimental solution for the massive production, as the alloy-cast wheels, never produced because this type of wheel was easy to break, because of the poor quality of the Russian aluminium and the conditions of the roads. The “Rotor” has a look similar to some Japanese realization of the period…but, like the previous prototypes, it has still the same frame and 4-speed gearbox of the old Dnepr, and even the drum front brake! This range of bikes shown the interest of the Soviet industry for the Wankel engine, although this work never improved the modernization of the normal production.

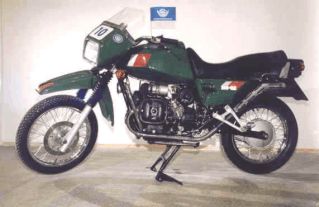

Moreover, the Dnepr realized also a “maxi-enduro”, in BMW R100 GS and Cagiva Elefant style! In the four pics above, the Dnepr “1000 Enduro Dinamit”, probably realized in the early ’90s. The engine was a new 1000 cc., with 5-speed gearbox, Bing carburettors and electric starter, with a power of 70 hp, very good for the maxi-enduro class of that period. That engine was intended also to be mounted on a new range of Dnepr 1000 cc. models. On the “Dinamit”, there were also a front disk brake (drum on the rear) and even a monoshock suspension! Also this bike remained a prototype, a shame for the power unit, but not for the coachwork…

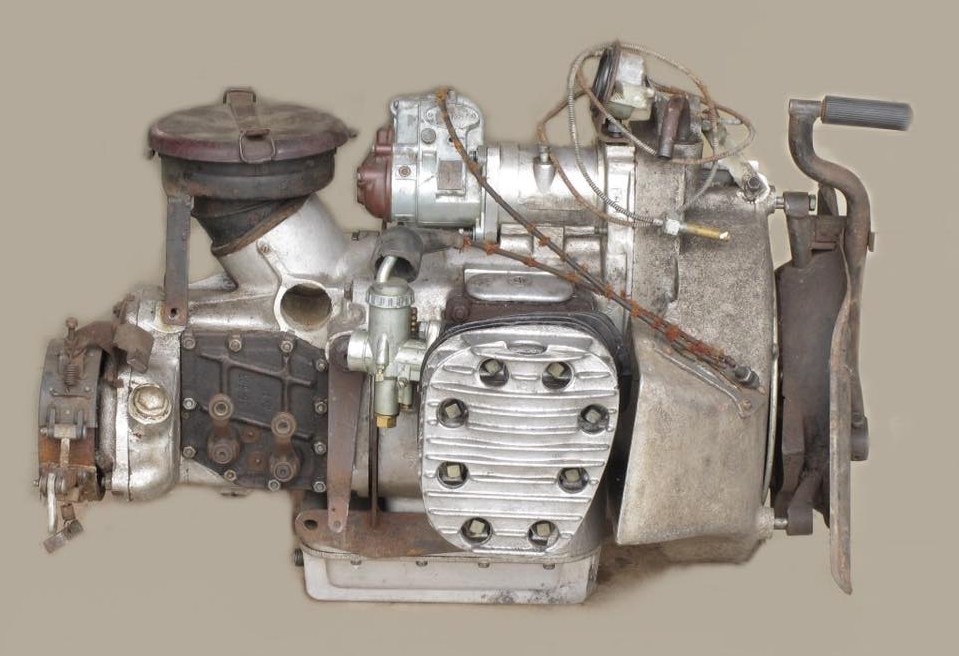

Dnepr Dynamite

Dnepr seems similar to the Ural, but the engine is totally different, with alloy heads and cylinders, in the Ural 650 engine these parts are in pig-iron, although the new Ural 750 engine is realized now in aluminium. The oil pump is located in the front cover of the engine, in the Ural it’s located in the crankcase, driven by the camshaft. The rocker cover from the Dnepr is rectangled and from the Ural it’s ellips. Crankshafts are different, connecting rods, roller type bearing for the Ural, and shells (slide bearing) for the Dnepr. But the most important difference is the gearbox, semi-automatic in the Dnepr, the change of speed is possible without the clutch lever. Dnepr has rounded mudguards, Ural has more squarer mudguards.

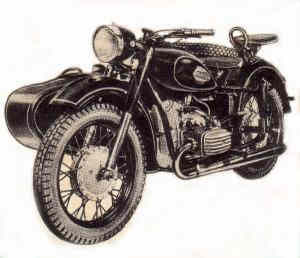

Dnepr K650/MT9/MT10

649cc OHV, 32 bhp. 1968 to 1974 This motorcycle was developed from the Russian Ural. Very little difference between the K-650 & MT-9 except the MT-9 usually had a 4-speed and reverse gearbox and the latter a squarer fuel tank. The K-650 replaced the K-750

Main differences between K-650 and MT-9 was new gearbox with reverse and automatic declutching mechanism, but also the cylinder heads on K-650 had longer fins on carburettor side than later Dneprs.

The K-650, MT-12 & MT-16 are very close models in that the Dnepr 12 uses the running gear of the Dnepr 11 & 16, and as the Dnepr 12 was a military model the MB650 sidecar drive has been used with the diff lock. 746cc SV, 26 bhp. Mid 1970’s to 1984. Sidecar wheel drive is through a split torque differential, based on WWII BMW R75 system. Fitted with 4-speed and reverse gearbox. Mainly for military use in USSR. The main difference is the replacement of the KMZ OHV engine with the 750cc SV. However, even the different engine uses the same ignition (manual advance distributor) and 6 volt generator, electrics etc. as used in the K-650 & MT-9. The 750cc engine is also used in the Ural M-72 and the Dnepr K-750.(with slight differences between the engine per model)

649cc OHV, 32 bhp. Used the MT10.36 or Dnepr 11 engine. Mid 1980′s to the closure of the factory in the late 1990′s. This is the military version of the MT16 which has the 2-wheel drive but with a differential lock. The build quality is reputed to be much better than the civilian models and had a paint rather than chrome finish. KMZ produced these motorcycles for the Soviet military on a special production line at the Kiev factory. They were used as reconnaissance and communications vehicles by the Soviet Army into the 1980s.

Translation ©Evgeny Radchenko 2014 especially for b-Cozz.com

What killed KMZ?

The director of the plant was dismissed and in his place came a man in general without any technical education. He was a member of the party of the regions of that time, under the guise of the reformation of the factory. Entire shops were closed, and was left only one shop. Not only that, the plant being located in the heart of Kiev, estimate the value of the land! The plant had contracts to supply motorcycles. The KMZ plant was a direct competitor to IMZ in Irbit. In the world there are only three plants producing such equipment. IMZ Ural and the Chinese Chang-Jiang, which by the way makes the M-72 750cc in the old style and even according to Soviet technology, but the Chinese are not particularly competitive because of the quality of the metals and details. For KMZ a miracle did not happen, it was sold at a basement price to guess who? A right-Russian company and the Russian oligarch, and this is not politics? That’s how they removed KMZ from the world market, and IMZ in Irbit suddenly became the ONLY company producing such a technique, and since it is unrealistic to make it inexpensive for the masses in today’s cost environment, the plant began to promote itself in the west, competing with the price of Harleys. By the way. according to the same scheme, not one manufacturer of Ukrainians was removed from the market. just one state, concealing itself with various slogans and flattering speeches, disorganized the army. and turned it into a sales market of 49 million people. thereby providing the work of its citizens with the currency of its state. It seems that if all the bikers, fans of the motorcycles. everyone will sign a petition to the president, they will meet with him. then not everything will be lost. The plant can be restored, maybe not in the old rooms, but among the bikers there are very serious people. strong engineering brains, talented innovators and enthusiasts, for whom the history of the plant after so many years means a lot, but investors? They come to where there is a spirit, and believe me, this spirit is still in every detail of the Dnepr motorcycle.

sources:

- «Днепрмото»

- Удав Удавович

- Aleksandr Kardash

- JD

- Nidgeybatfink

Observations/Notes:

There were two versions of the “Stubbie” leading link front forks. Early version used roller bearings, later version used ball bearings.

(note Catweazle) I never saw ball bearings but I’ve seen slide bearings used, steel and bronze.

There’s also a difference between Ural and Dnepr brake plates.

Motorcycle K-650 had more flared mudguards ends and cylinder heads had longer fins on inlet side. These longer fins were reduced on model MT-9 onwards.

*Gearbox MT804 with reverse gear and automatic declutching mechanism (foot clutch). Also there was made a gearbox MT804 without reverse gear mechanism, the reverse gear hand lever was omitted for MT-9 solo motorcycles. These thus allowed a 5-speed arrangement. Gearbox MT804 interchanged with old-type “crash” gearbox, with shorter driveshaft length required.

MT-9 had a high profile camshaft. MT-10 had mild camshaft. MT-10 had increased diameter inlet valves.

Parts stamped with a star were from military assembly lines quality control.

Sources:

- KMZ

- Great Russian Encyclopedia of Motorcycle

- Moto Moscow Russia

- Avtoexport Round-Up Moscow USSR

- Steve Wiggins

- Andy Gray

- B-Cozz archives

Kievskiy Mototsikletniy Zavod