Text by Andrei Myatnev, photos from author’s archive

So we continue our journey into the history of [Soviet] domestic motorcycle industry. This time we will speak about motorcycles in their classic meaning as “grown up”, big engine capacities, noteable power output, etc. Worth noting that in a magazine article format we cannot discuss all motorcycle models, so we will stop on basic, main models and enumerate most interesting experimental and small series types of machines. Let’s start from biggest and most productive plant of Soviet motoprom – Izhevsk.

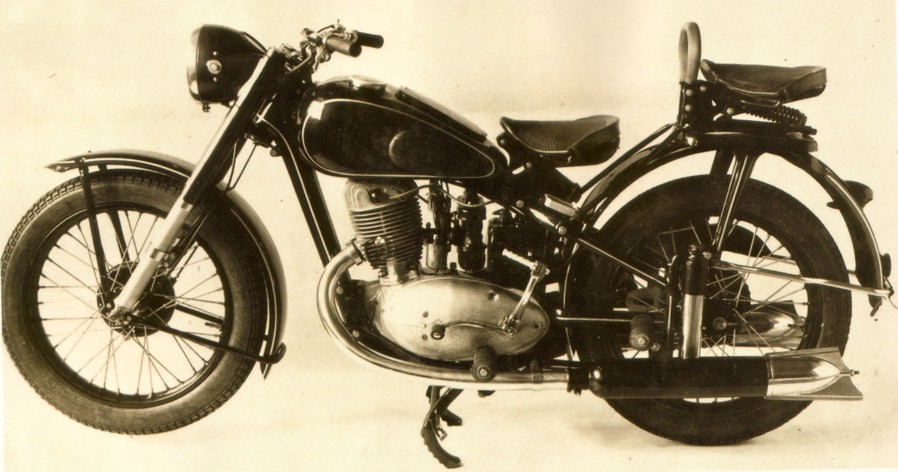

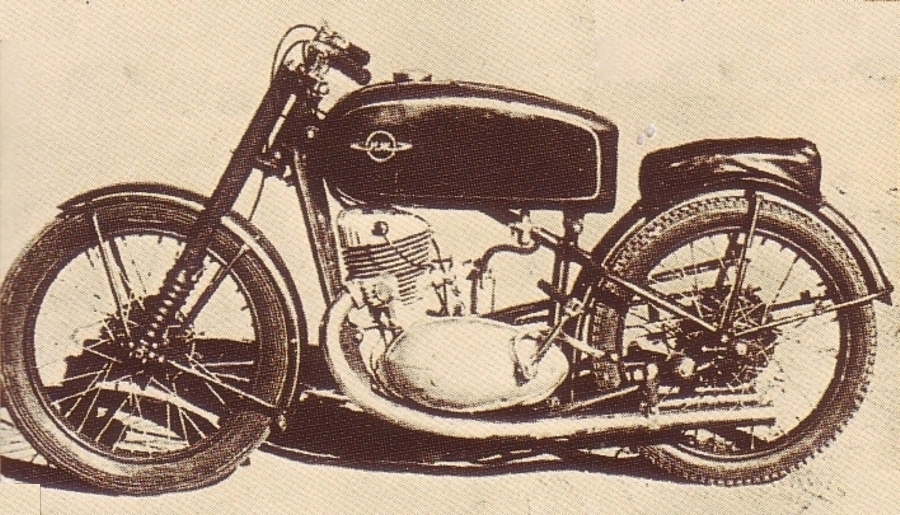

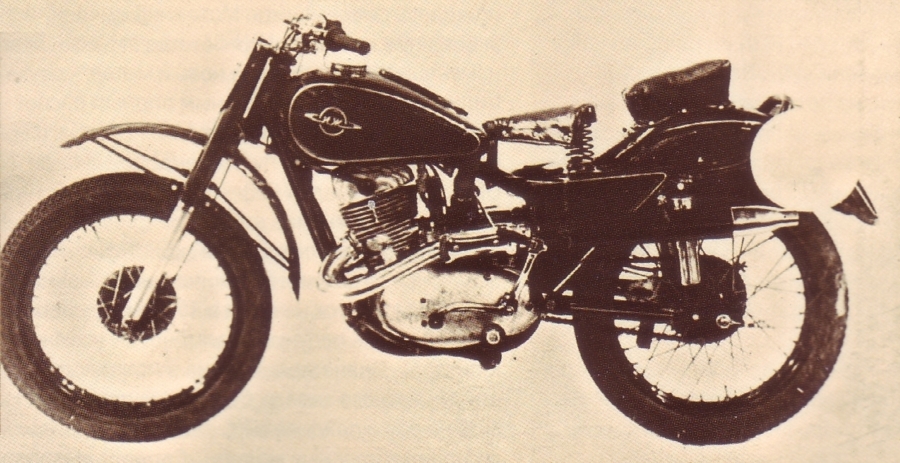

Izh-49 model, which was mass-made since 1951 became one of the most widespread on territory of the USSR, as more than half million motorcycles were made. Since 1956 the model was issued in sidecar version, while Vyatsko-Polyanski plant (later “Vyatka” motorollers were made there) and produced sidecars for 49th. The 49s were popular among the public and reputed undemanding much technical servicing, namely this model became the first to be exported and IZH brand was then known abroad. The plant’s designers department made several modification based on 49th for sports: Izh–50A motorcycle for road races on a circuit, Izh-50B for cross, both had engines with 16 hp and were considered rather advanced machines for the USSR of that time. In 1955 a new generation of sport motorcycles with new chassis appeared, they got welded frame and rear pendulum suspension. Typically IZH plant would try all new designs on sports machines, which if successful were later used in mass-made models. First came Izh-54 road race version, (here not 10 but 18hp), and Izh-55 (for cross and multi day races), 18 hp. All versions of Izh-55 had carby, air filter and ignition well-insulated from dust and water, exhaust pipes and silencers raised, cross tires and good shock absorbing suspension. Beginning mid 1950-s the IZH plant started mass-production of sports motorcycles for road races, cross, multi-day events and later for conventional and ice speedway competitions. All machines were spread between Voluntary sports clubs of the USSR and were not sold to the general public. Besides experimental designers workshop of the plant was to carry out special orders on making machines that would take part in international competitions and rallies, often factory racers performed on these.

In 34th international six-day races, held in Czechoslovakia, 1960, racers from Izhevsk won Big gold medal of FIM. In 1964, next international FIM rally the USSR put out 14 racers from Izhevsk, who took first place in team classification. Two years later, 41st FIM six-day races in Sweden, Soviet racers equipped with Izh-55M won gold medal. There are many more achievements but these are enough already to see scales of IZH plant role in motorsport of those years.

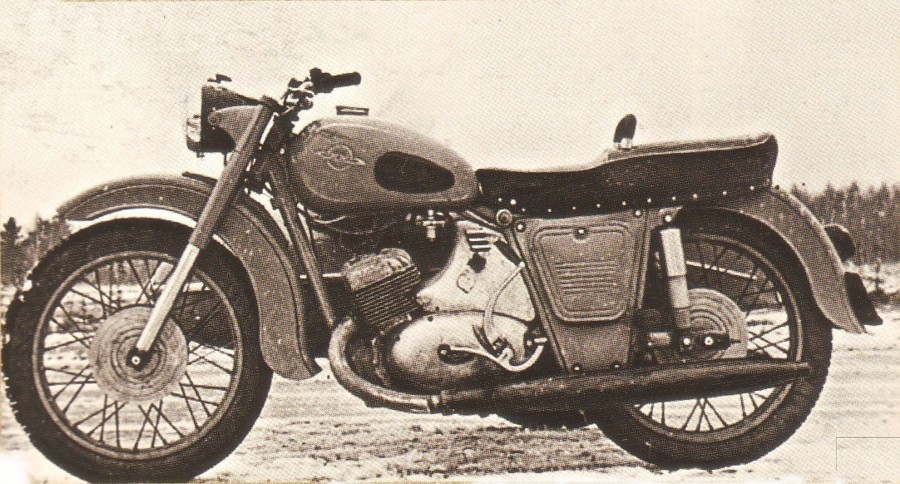

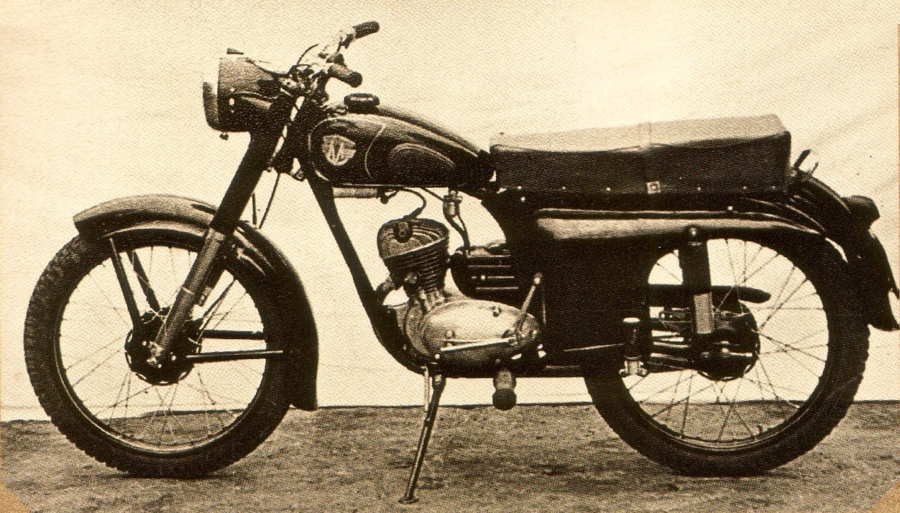

In 1956 the plant assembled a probe series (pre-series) new model Izh-56, which was supposed to succeed “49th”. In fact, till 1958 both models were assembled simultaneously when the new model technology was made perfect in details. In design the model differed from preceding machines of the factory especially in chassis, as welded tube frame (IZH-350 and 49th had frames press-formed assembled with bolts), interchangeable wheels, deep mudguards and housings covering chain final drive and carburetor assembly with air filter. There are new technical design decisions used in this model: engine output was 13 hp, and alloy jacketed cast iron sleeve press-fitted in it, gear box shifting was done by foot, 680,000 Izh-56 assembled, 120,000 of them were equipped with sidecars by Vyatka plant. By the way, 10th July 1960 a millionth motorcycle got off Izh plant conveyor, which happened to be Izh-56, 2 millionth motorcycle was then assembled in 1965! The model Izh-56 was made till 1962, succeeded by a new model Izh- Planeta, practically an improved “56th”.

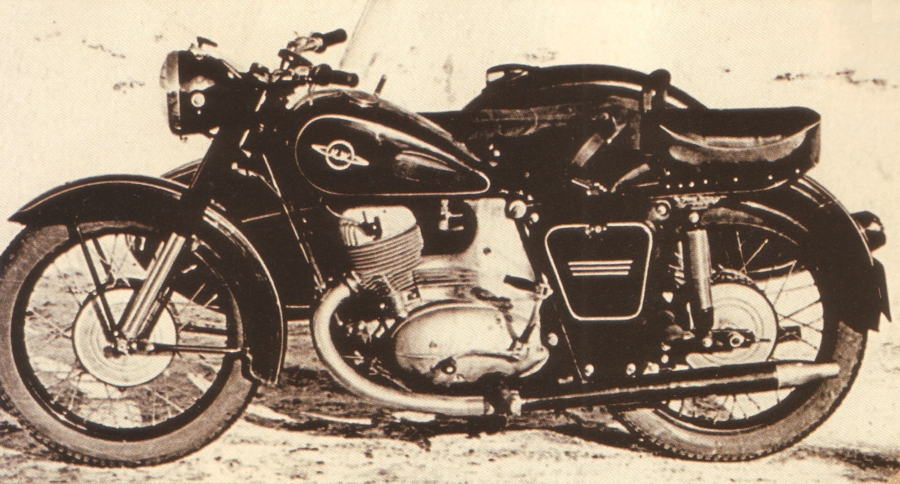

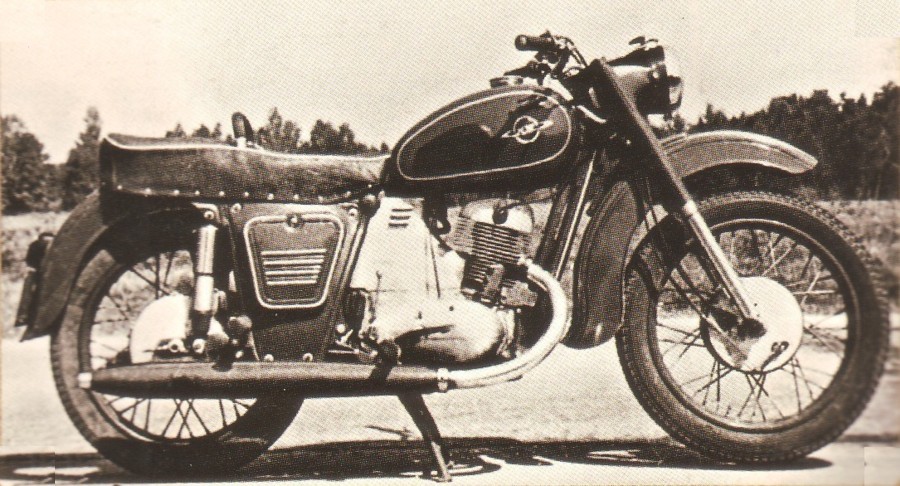

Since 1956 the plant’s designers department had been working on new two-cylinder model first referred to as Izh-58, an experimental sample was made in 1957 and was exhibited in USSR hall of international Brussels exhibition in 1958. A long term, multilateral test of the model in Serpukhov and at Izh proved many underdevelopments, so mass-production had to be postponed. The machine inherited chassis from 56th but a completely new engine, in-line vertical twin, air cooled. Izhevsk designers chose same way as German DKW factory that had similar twin cylinder model mass-made in 1930-s, but made that design better and up-to-date. Mass production started in 1961. It was now then called “IZH-Jupiter”, although “planet topic” would continue with IZH brand machines for later periods, as Orion, Saturn and Sirius models (pre-series samples) would be made.

But let’s go back Jupiter, when this type of motorcycles appeared all production of IZH factory was divided into single cylinder (Planeta and others) and two cylinder (Jupiter and its successors) while both families had unified chassis. Such approach offered mass production of different types of motorcycles in great volumes at low costs.

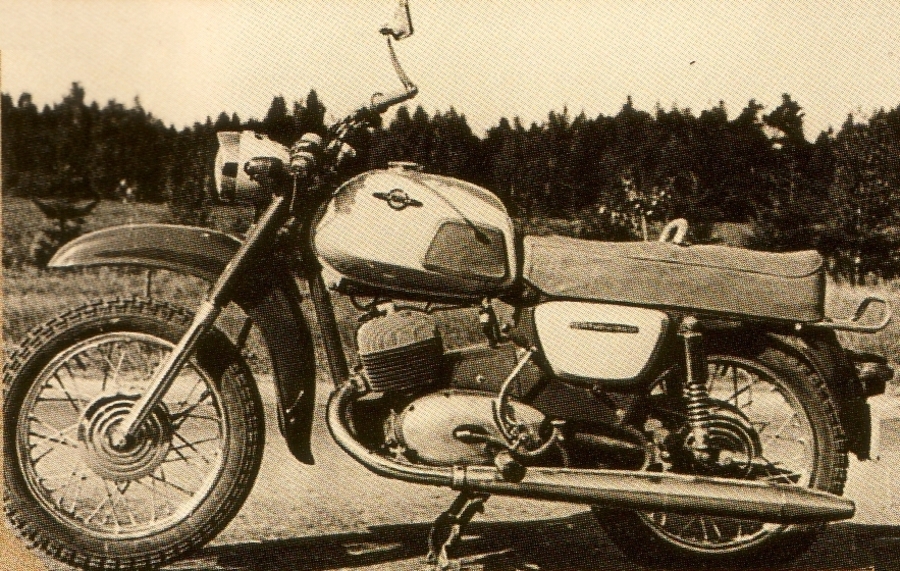

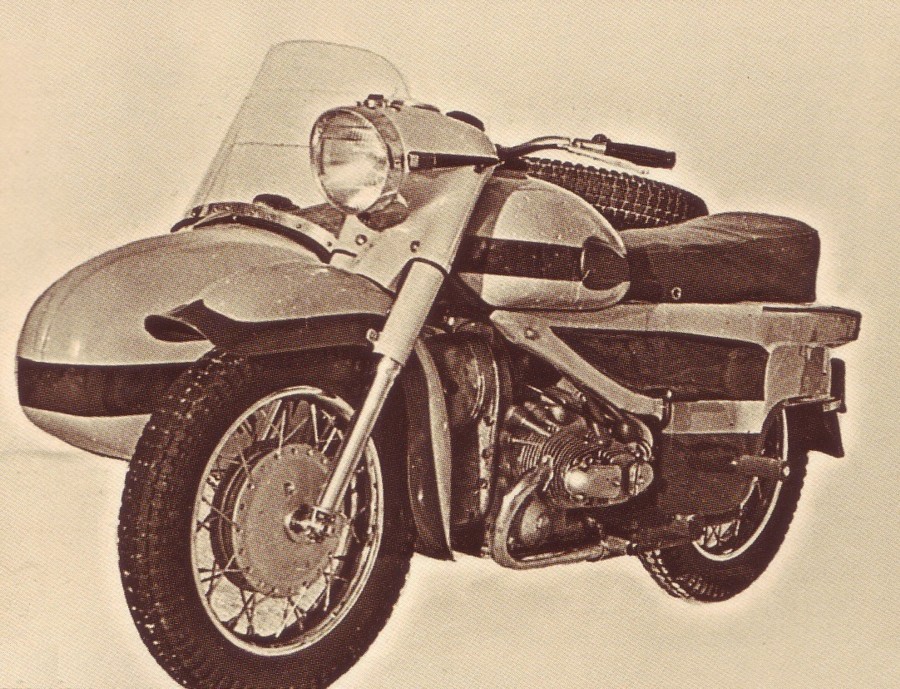

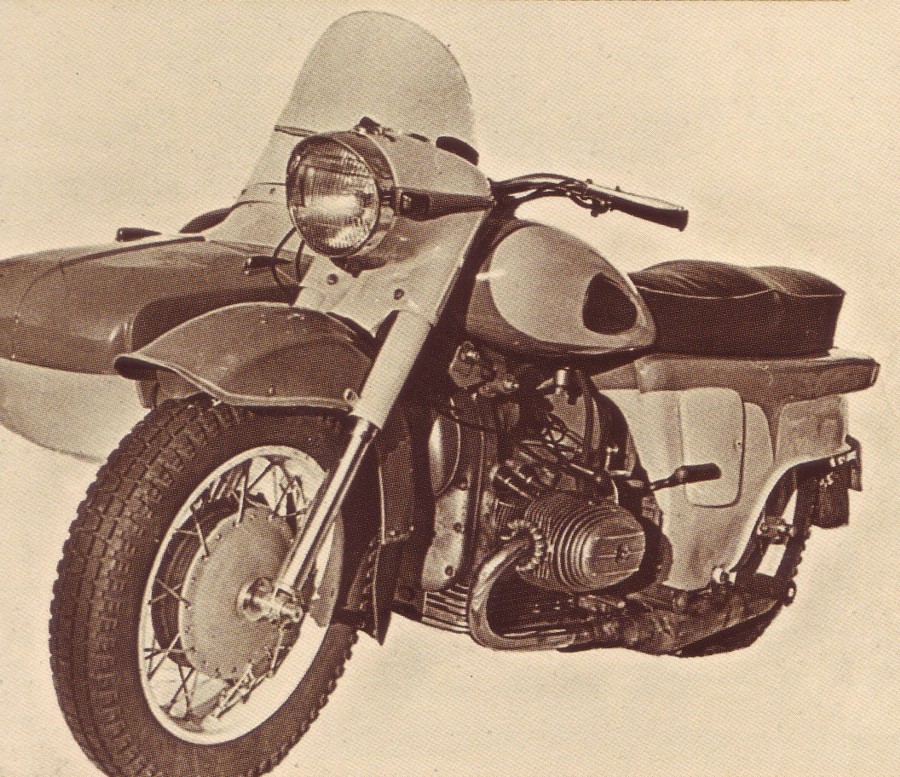

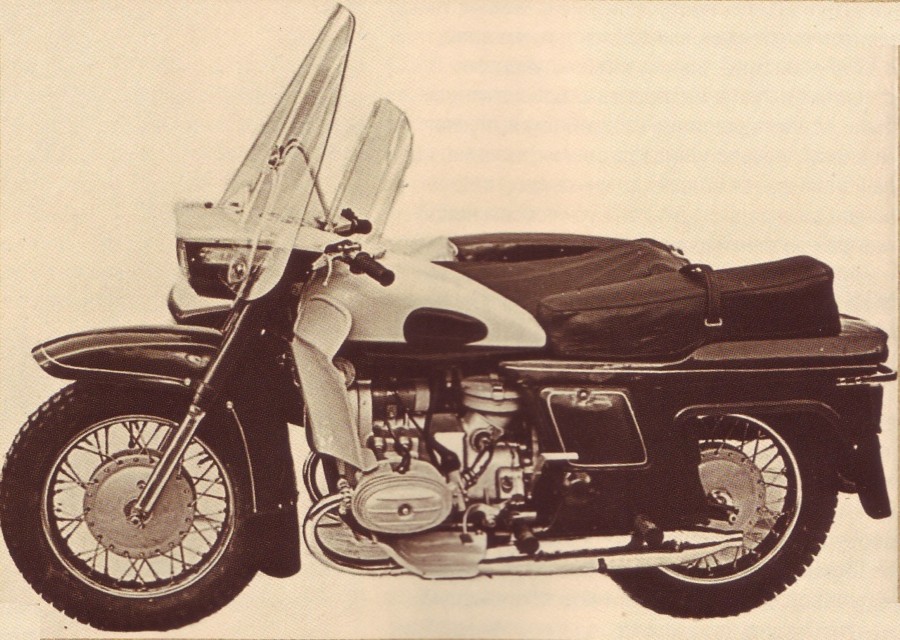

IZH-Ju (also a formal name mentioned in catalogues) had 18 hp engine and was issued as a solo or sidecar variants traditionally, the sidecar version had factory name “IZH-JuK”. In 1965 improved versions Izh-Ju2 and Planeta-2 were issued, both had enhanced technical and economy qualities. In the mean time the plant’s design department was working on new prospective generations to take after “Ju” and “P” of second model generation. These models were named IZH D-12 and IZH D-14 unified in chassis and having two-cylinder engines 350 and 500cc correspondingly. A couple of years before this several versions of 500cc IZH-555 were made, but they were never represented to Ministry body inspection (transport means tests) , as they only served as “in-laboratory species”. Experimental samples of D-12 and D-14 were assembled in 1966 as two years were spent for testing and finally in 1968 these two machines were put forward to official testing bodies, after which a decision on admittance to mass-production was made. The new machines passed all tests normally and … were not allowed to conveyor, as higher chairmen in charge decided that newest and advanced models to be mass-made were unreasonable due to economical issues.

(Translators note: First want to say that I have never heard any such nicknames myself in my area, unless i knew that a person read this or that MOTO magazine issues and there Minsk was referred to as monkey, in Rus, somehow not close similar to minsk sounding. Minsk in older my granny times generation was named Kozel (“goat”) while referring to izh-49 or Minsk models…)

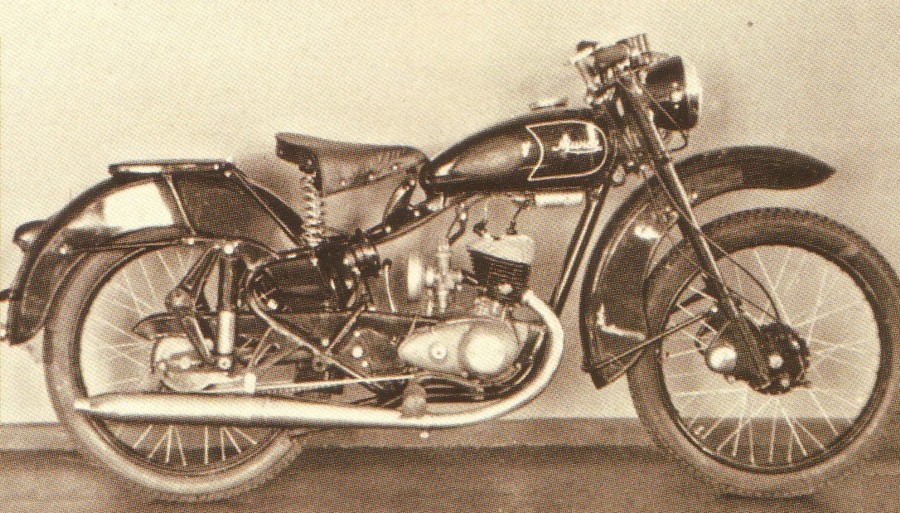

Minsk motorcycle and bicycle plant (MMVZ) history sprang from first after war year, when half demolished city began rebuilding. At first bicycle production was set rather quickly, aided by industrial equipment from Germany that was sent as war reparations. In 1951 Moscow motorcycle plant was closed and all machinery, technical documentation and a part of staff moved to Minsk, so Belorussian capital began making motorcycles. Since 1951 MMVZ made M-1A, a famous “monkey”, in fact latest machine version with telescopic front fork of former Moscow plant. First M1-A had old type girder front fork, 2nd variant had telescopic front fork. In 1954 Minsk plant designers and their colleagues from Serpukhov experimental design department of motorcycle building (Serpukhov TsEKB) devised and assembled few “M-31”, a possible future model for Minsk plant conveyor. The machine reminded German Simpson AWD-425 in arrangement design but it was not a copy. Minsk machine was equipped with 4-stroke 350cc engine, 1-cylinder, OHV and 4-speed gearbox with foot shifter, final shaft drive, rear wheel suspension with hydraulic shock absorbers and telescopic front forks. Engine developed 18 hp and pushed 160kg machine to 110 kmh. M-31 proved a noticeably advanced machine for its time, it passed testing successfully and got excellent marks, but was not mass-made, as Ministry authorities decided that Minsk motoplant ought to make light class motorcycles, while such an advanced M-31 is ahead of time for the USSR. So strange conclusion was.

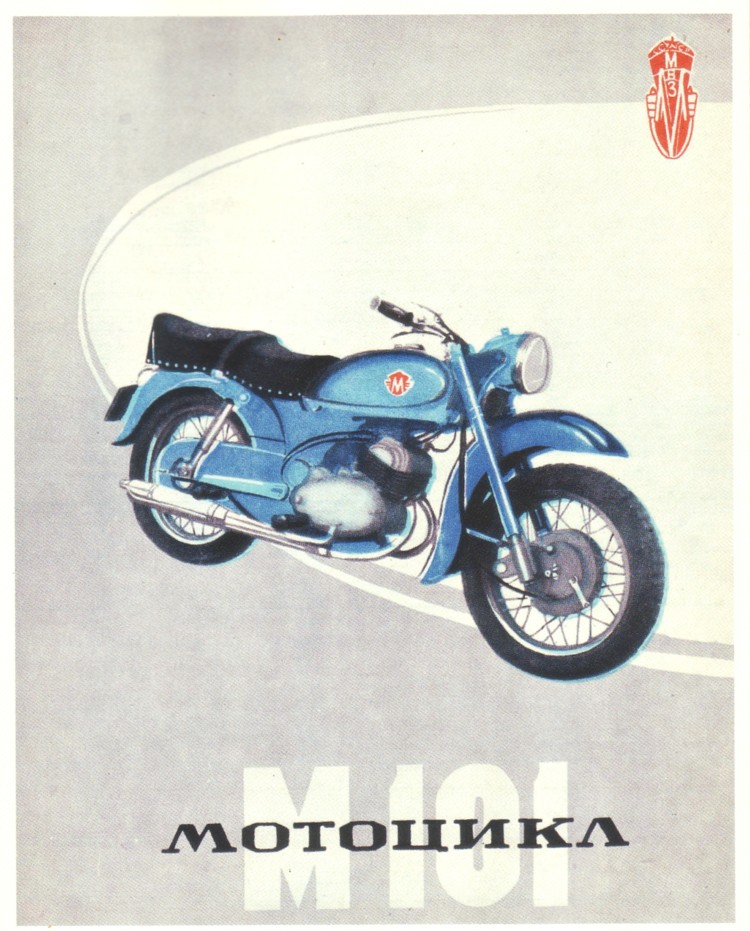

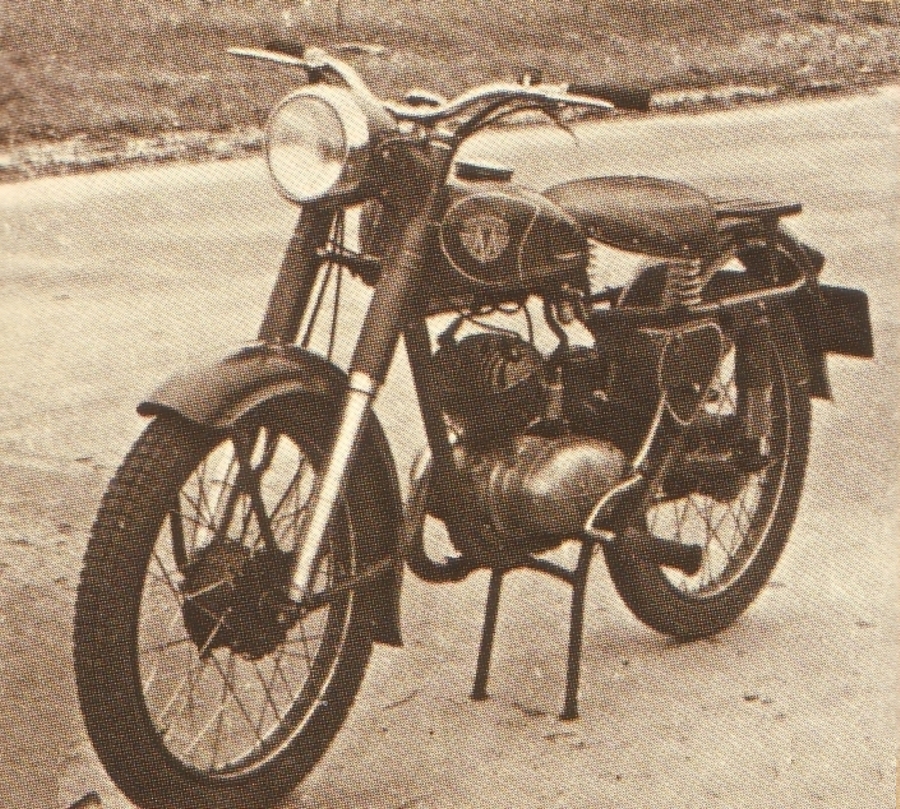

In 1956 mass production of Minsk factory own design M-1M “Minsk” started. It had original frame with spring suspension and friction dampers. Short lever front fork, deep mudguards, its engine unchanged M-1A, but thanks to a new carburetor its power grew to 5 hp. Electric system was also different, as AC generator could spare battery to start and run. In general, the motorcycle was not a beauty, though comfortable and reliable when ridden. With M-31 failed and still hoping to come out of “a doomed circle” of 125cc class, one more original machine was created with 250cc engine and named “M-101”. This was an accumulation of non-standard engineering solutions, for example, the engine was mounted by its side to press formed steel back bone type frame, which improved air cooling and offered engine dismount in minutes! Both front and rear suspension had hydraulic shock absorbers, wheels had uncommon for USSR sizing 3,25×16”. Nevertheless, after several pieces had been made, the project was closed with same reasons as for “M-31”. Interesting to note that council of economy of Belorussia soviet republic published brochures for this model, hoping it will be mass-made. These brochures are now enjoyed by collectors, but none of the machines survived.

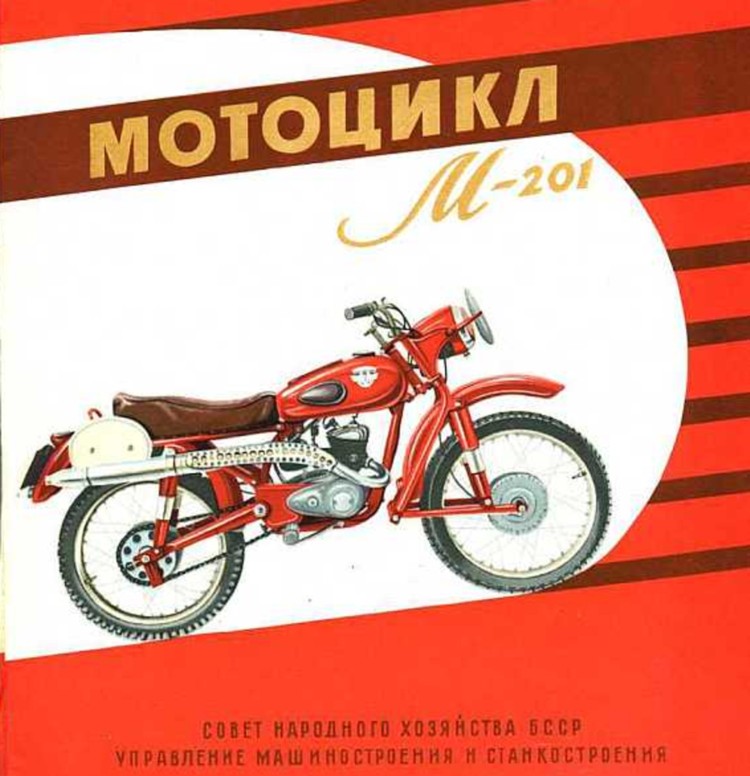

In 1957 the plants designers started work on cross and multi-day race machine labeled “M-201”, by beginning 1958 several samples were made on which factory racers took part in competitions. Testing results were positive and the factory assembled a small series of M-201 for sport clubs. Its 6 hp runner pushed 90 kg machine to 70 km/h.

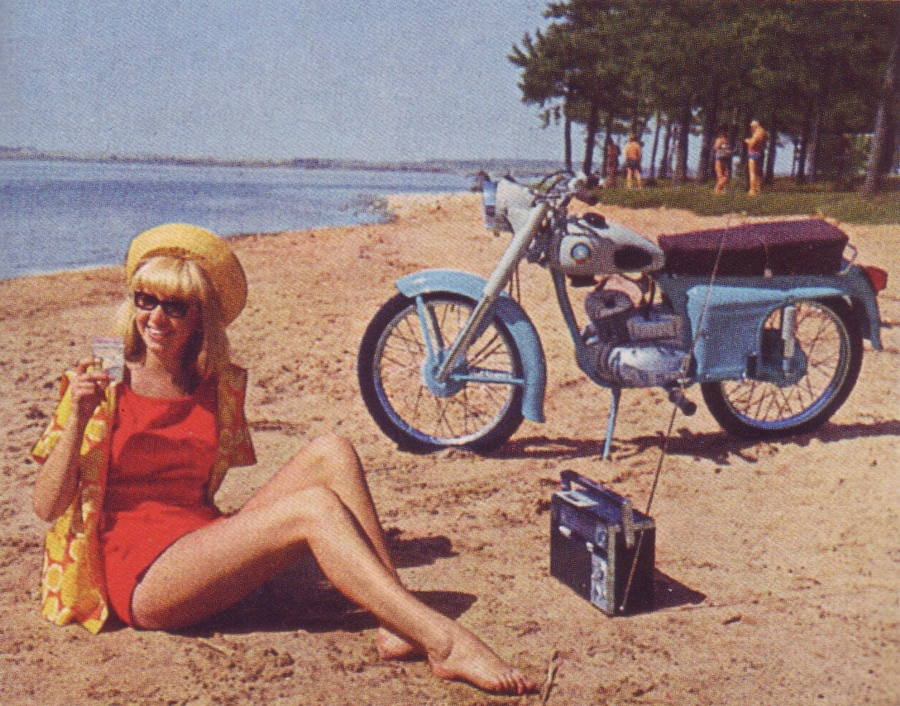

In 1961 Minsk plant redesigned and modernized mass-produced M-1M, front fork was then telescopic and rear suspension got hydraulic shock absorbers, engine service life increased as oil catching air filter was installed, top speed grew to 75kmh. This model was named M-103 and had been made till 1964 when it was succeeded by M-104, with different carburetor and side covers on its frame and two-seat one piece foam saddle, in other details it was same as its prototype. In 1966 M-105 mass-production started with 7 hp engine and 4-speed gearbox, while chassis was same as M-104. In general, motorcycle production in Minsk may be called very conservative, but the plant’s workers should not be blamed, as production policy was dictated by chairmen of Main body of motorcycle and bicycle-prom and the Ministry.

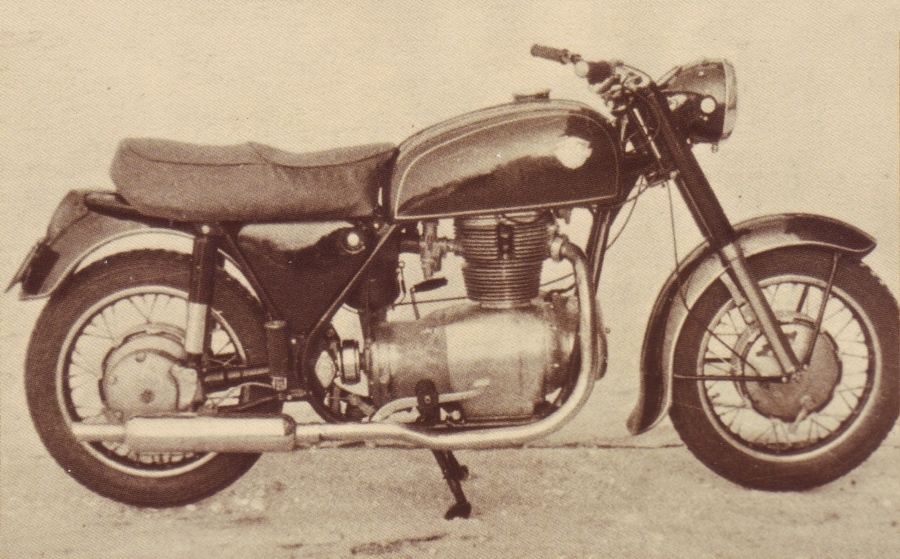

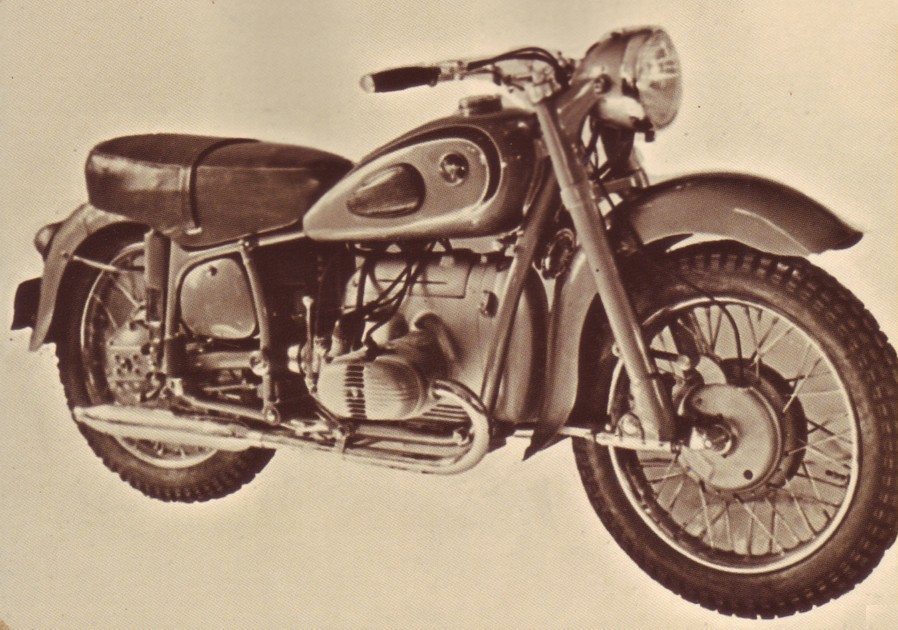

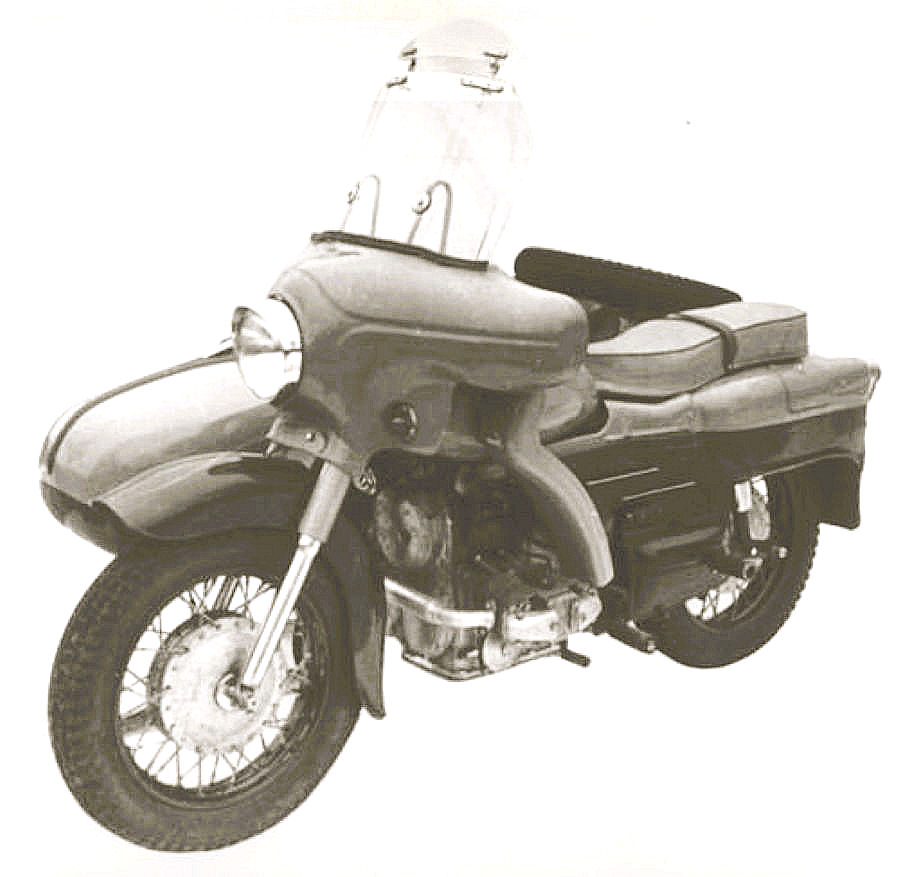

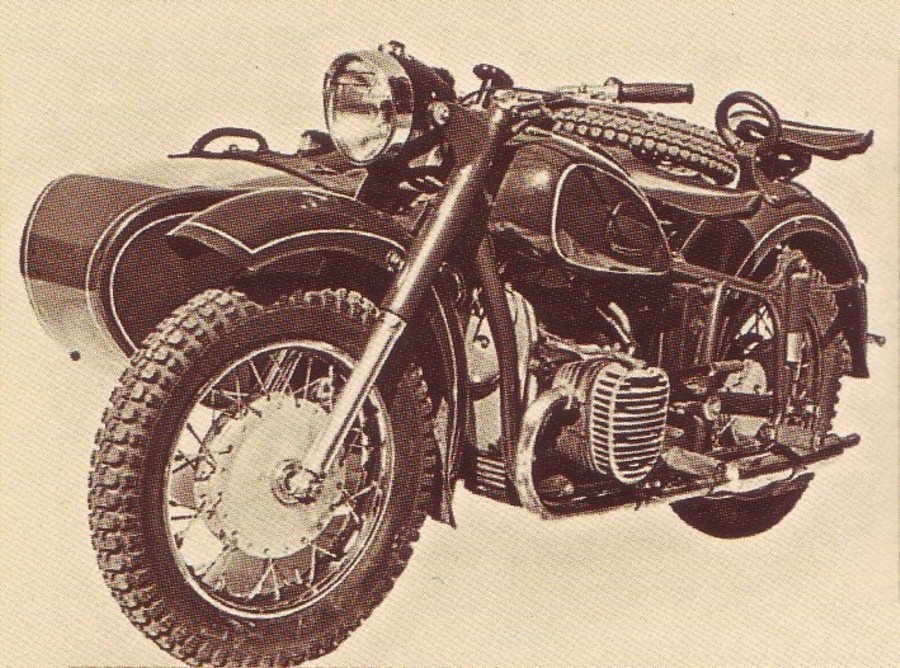

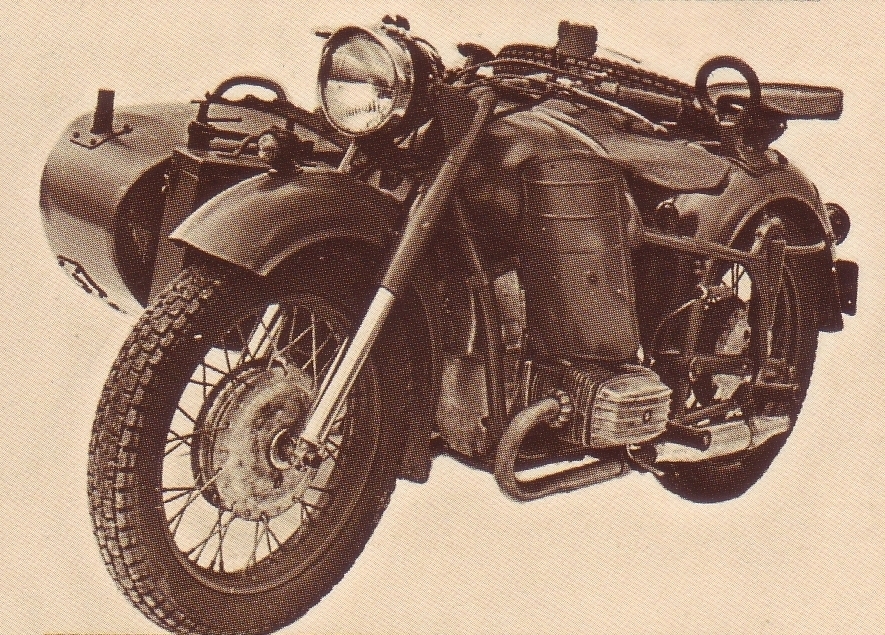

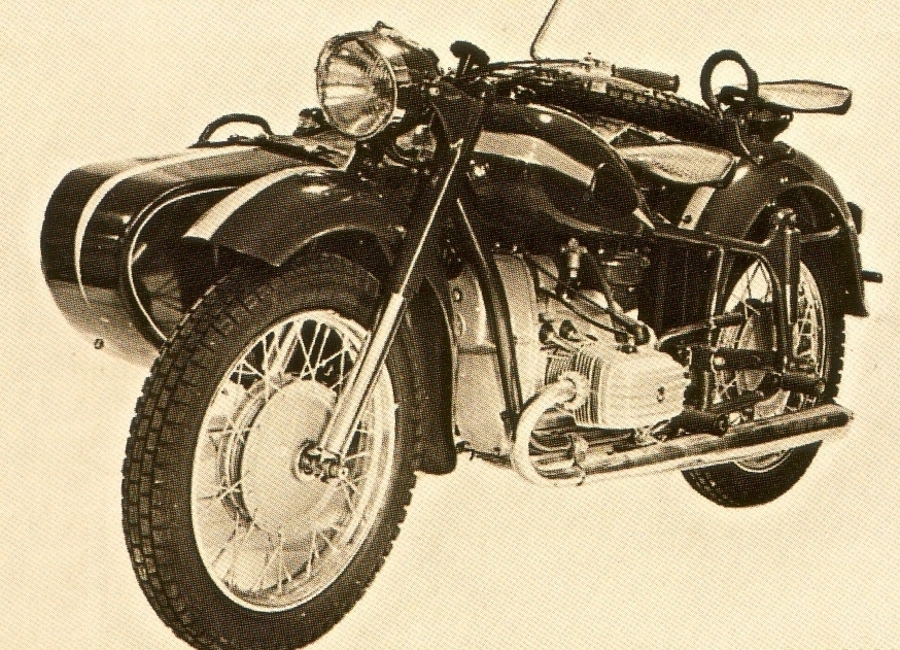

Kiev motorcycle plant was initially supposed to produce small capacity machines – engine bicycles, but in 1951 it was reassigned to make M-72s for army needs, of course. Equipment, technical documentations and partly staff was moved from dismissed Gorky motorcycle plant (GMZ) in the Volga river region. Mass production of heavy motorcycles started in 1952, as engine bicycle “K-1B” and ”K-1V” tricycle for people with limited capabilities production ended a year later. At first only engines, gear boxes and final drive gears were made at KMZ, while most parts of chassis and the rest came from Irbit plant (IMZ). Gradually motorcycle full production and assembling was set at KMZ, so co-work with IMZ became unnecessary. Designers department run by K. Pozdnyakov added by experienced engineers from former GMZ took to developing a new project of “motorcycle for domestic needs”. As a result model M-53 came to the light in 1953 and was very advanced technically for its time. Its 4-stroke 500ccc OHV opposite engine developed 28 hp, chassis had an original design with rear pendulum and hydraulic shock absorbers suspension, short lever front fork, alloy wheel hubs with powerful drum brakes. The new machine took very little from M-72, as it was thought technically and morally obsolete. M-53 passed all tests and got high marks from specialists of Serpukhov experimental motorcycle building department but was not mass-made, only 5 pieces were assembled. Ministry of automobile and tractor industry decided that making an expensive and new machine is ahead of time and an approach of modernizing mass-produced model should be used. Ought to say that with same verdict many other prospective models were rejected and not only in motoprom but in all fields of scientific and technical activities. “State planned economy, damn it!”, some sharp tongue designers reacted , feeling sorry for their job done in vain. Many design traits dissolved in following two decades were used in other mass-made KMZ models. Modernization of M-7 2 dictated by the Ministry gave way to M-72H (produced 1957-58) and K-750 (produced 1958-1964), while a modernized version K-750M was assembled on KMZ conveyor till 1969.

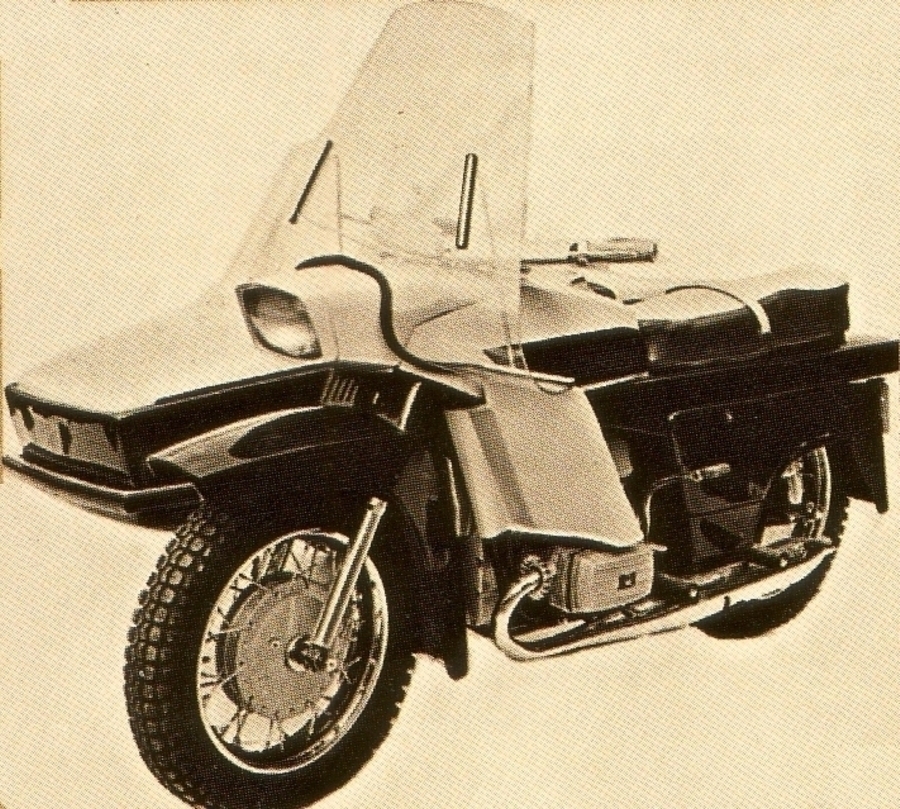

Beginning 1960’s KMZ designers supported by the plant’s director attempted to create one more prospective model, as a first result there appeared 650 OHV engine surpassing in tech specs all previously made Soviet engines. Models were labeled MT-2 and MT-3, a characteristic design of these machines were open type frames with engine mounted by its one side , though MT-2 had a press formed frame and MT-3 a welded tube open frame, in other details both models were nearly same. Drive tests revealed unsatisfactory engine service life and lack of frame rigidity. Work on mistakes had been done in shortest time and resulting new models was named MT-5. Its engine design was revised, added by centrifuge oil filter and different cylinder heads. Frame remained open-type but reinforced with pressed steel elements covering rear part of the motorcycle. Tests and driving did not complement designers expectations, so in 1967 there came out MT-7, retaining MT-5’s engine but open type frame design was declined for classical tube frame. And “bad mark” again, motorcycle did not pass tests. Next year MT-8 was represented with improved engine 650cc. Creating this machine “methods of art design” were applied for the first time. What was meant by those words is not surely known now, but outer look of the machine corresponded to those days advanced criteria. MT-8 passed tests and its mass-production was permitted by special commission on condition that “all odd art design ought to have been cut off” and “M-72 resemblance should have been kept”. So Kiev workers braced for final leap and turned the machine’s outer design to that of 1930-s. Resulting model named K-650 “Dnepr” became new mass-made model since 1968. To summarize, in 10 years KMZ plant made consequently 6 models of heavy motorcycles, only one of which became mass-made, with crucial new design characteristic we can mention engine and frame with rear wheel suspension. In other parts “Dnepr” differed little from preceding “K-750”.

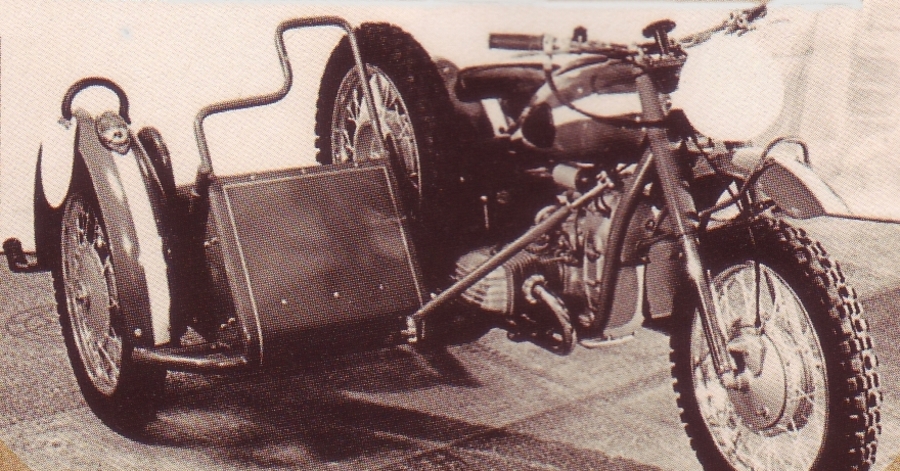

Beginning 1960’s KMZ began to mass-produce off-road motorcycles MB-750 derived from “K-750M” with differential drive of sidecar wheel and blocking differential mechanism, boxes for munitions and a mount for a machine gun. These machines were made exclusively for the Soviet army and were never sold to general public. In 1969 new model for the army “MB-650” was made based on “K-650 “Dnepr” with same conversion method adding sidecar drive and differential blocking device.

KMZ thought of sports as well, so since 1968 small series of “650 MCM” were assembled. This was a cross and multi-day race machine based on “K-650”. KMZ 650 MCM was a reliable machine and appreciated by racers.

Sources:

- Andrei Myatnev.

- Steve Wiggins

- MOTO Moscow Russia

- IMZ archives

- multiply-bcozz archives

Translation ©2013. All Rights Reserved. Translated specially for b-cozz.com by Evgeny Radchenko, Russia,

Proofreading, editing by JD

Refurbished 2015 by Cat

Special Thanks Eugene!