Tulalogo

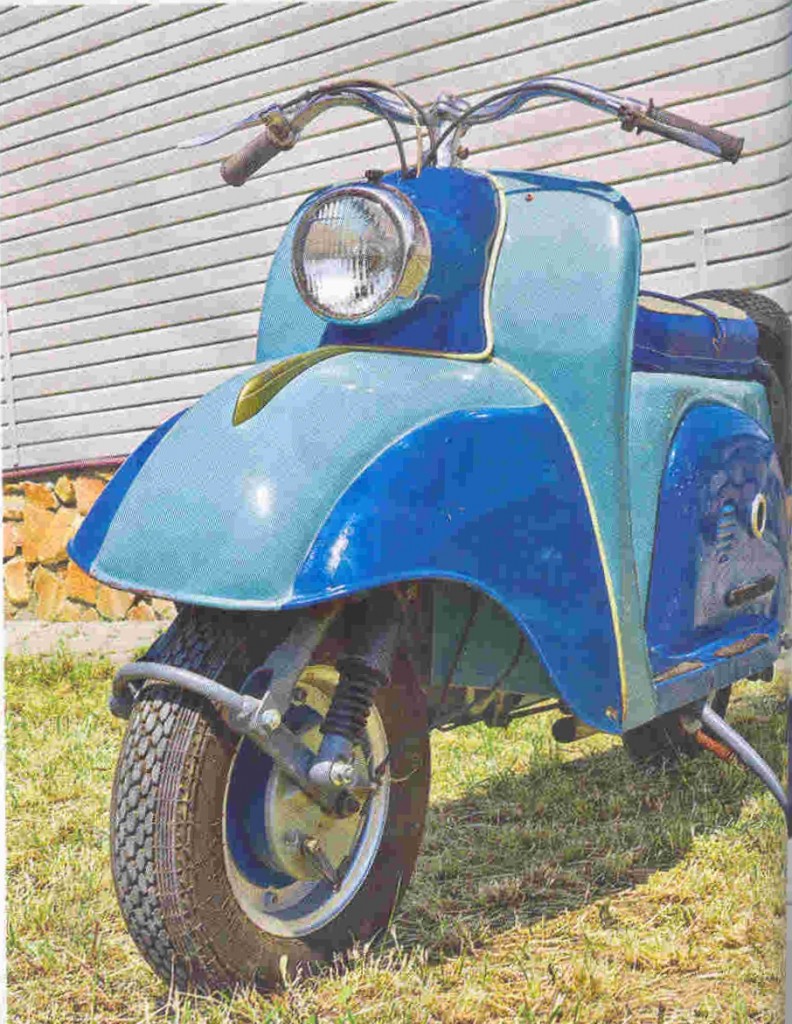

T200 1957

Tula’s first product – motoroller T-200. Official date of mass production start – 27 Apr 1957. Its prototype was East German GoggoTA55, though no license has ever been bought, a party of samples was taken apart, made design and technical documentation, some of which helped to do Serpukhov TSKB of motorcycle design. For the times trends the machine was a luxury, big mudguard coats, electric starter (first series din’t have a kickstarter, it appeared 2 years later on request of “proletariate”), cylinder cooling fan, indicator of switched gear, soft suspension with single tube shock absorbers, spare wheel. Quite heavyweght, with 160kgs “dry”, 200cc 2stroke engine developed 8 horsepower and top speed was 80 km/h.

T-200M 1961

The T-200 had a tendency of losing straight course at top speed ,”wobbling” on road, therefore development of improved T-200M started in 1961 was confined to eliminating this defect, front long lever “pusher” fork was substituted with “pulling”, accompanied by double tube absorbers – a standard at those times, engine was tuned up slightly, 9 hp. The outer look was easily recognisedable by better suiting “apron” (front mudguard), front fork, one vent hole instead of two in engine room coat.

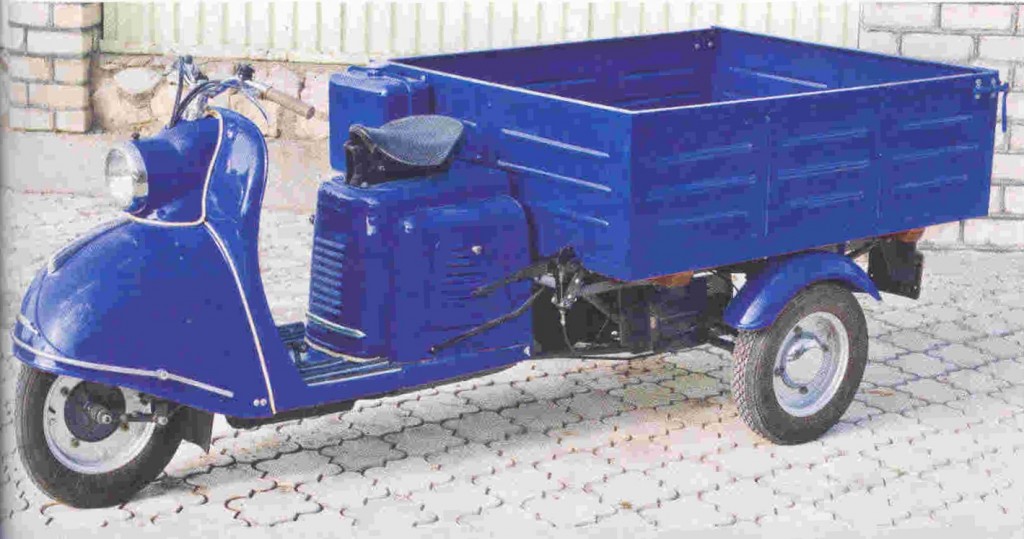

1959 Tula T-200 cargo

At the same time when production of two-wheeled started, a commercial, a 3-wheeled version was designed with cargo load up to 200kg. Powerplant was bridged by chain transmission to reducer gears, combining final drive, reverse and differential, connected to rear wheels by cardan shafts. Rear suspension – independent, with perpendicular levers. First the factory made commercials for its own needs only and later for other factories of Tula. Supply to other soviet cities was let out in 1959, while sales to general public were banned till 1980′s.

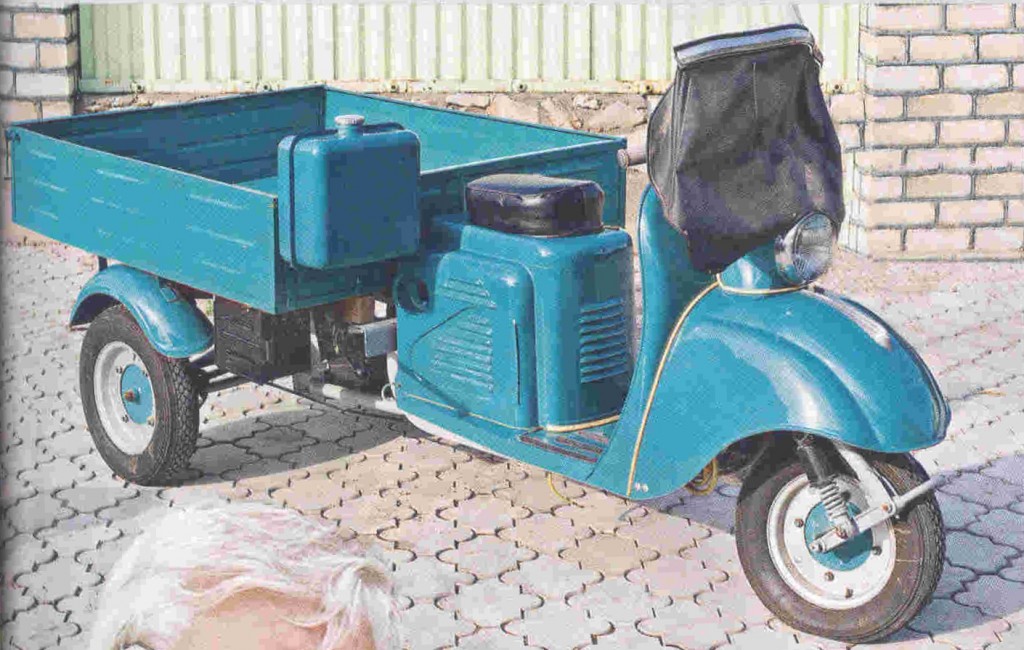

TG-200 cargo

Two wheeled motoroller version improvement was doubled by 3-wheeled version – TG-200: unreliable chain reducer borrowed from motorised wheelchair was replaced by toothwheel gears designed at the factory, parking brake of car type was changed for simplified latch-type, locking pressed brake pedal, windscreen with synthetic leather lower part was not adding any beauty to design look in general, though it proved practical.

T-200-M3 “Meteor”of 1959

Resulting modernized motoroller weighed less by 15kg was still considered too “heavyweight”, when a T-200-M3 “Meteor”, designed in 1959 was lighter by 30kgs! Actually, ripping off spare wheel, rear rack, electric starter…electric system and front body parts were borrowed from “Vyatka”

“Konek-gorbunok”

One of mystery making machines of our motorcycle industry- “Konek-gorbunok” (Russian fairytale magical flying pony): 350cc horizontal, short stroke engine, telescopic front fork, 16″ wheels was a standoff from Goggo “family tree”. For this were also designed cast alloy wheels, pneumatic gear shifting mechanism, pneumatic suspension- something any 2-wheeled vehicle could only have dreamt of in the 1960′s. The dream was never “approved” “from above” to be assembled at conveyor.

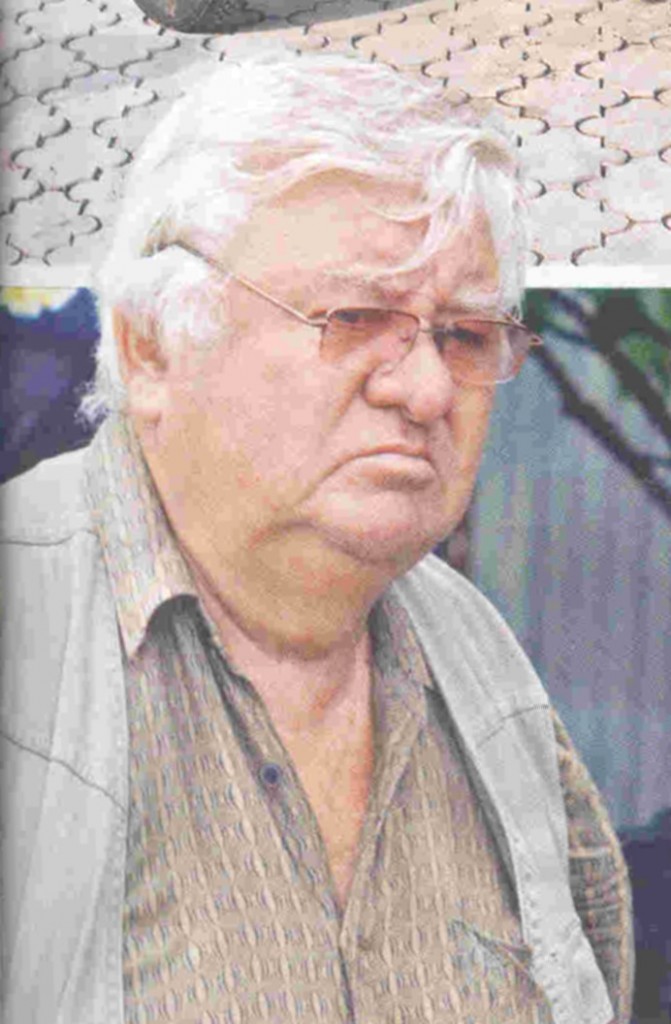

Leonid Pavlovich Zyakin

Leonid Pavlovich (patronimic) Zyakin – has worked at tula factory for a while, now his collection of motorollers, motorcycles and mopeds is estimated at 130 pieces, most of which are experimental, prototypes of German, Chekhoslovakian origin, the pictures of motorollers are from his collection. In the future he plans to organise a moto-museum for his own initiative and financial support, as neither Tula’s authorities, nor the factory expressed any interest to assist. You can see future museum at: http://retro.tula.ru/moto0.html

One of alternative ways of future Tulas – elegant motoroller “Start”, several different prototypes were built in mid 1960′, this motoroller has streamlined lines and 12″ wheels.

1967 – the famous Tula “Tourist” Scooter

Designed specially for 250cc engine, this machine entered mass production under the name “Tourist” with old 200 cc runner, new cylinder head with double sphere shape “jockie cap” raised power to 11hp, newly designed chassis had long lever pusher fork, (“Earles-type”, different from previous models), monocoque coat instead of tube frame. First soviet “motorcycle” to have turnlights, weight 145kg, top speed 85km/h.

“slimbody” Tourist Sport of 1970

Now called “slimbody” – experimental “Tourist-sport” of 1970 had cut out 20cm of coating in its center, improved look, lighter with better handling characteristics, unfortunately it remained in one prototype sample only.

same “slimbody” of 1970

A new 250cc, with “square” dimensions 68x68mm engine was made in 1962, 14 hp. Production rooms were freed and ready to make it with machinery. The factory was ordered to start production of… missile launching unit, putting a kibosh (an Irish word for “end of the line”, Ed.) on 250cc engine.

1962 250cc 14 hp

pama

Soviet factory teams didn’t take part in TT races, they had their own – factories competitions, racing against motorcycles on a cross track was not easy task for motoroller. The frame was hardened with welding on additional tubes, the silencer was raised, it did have small panels on it, not restored yet.

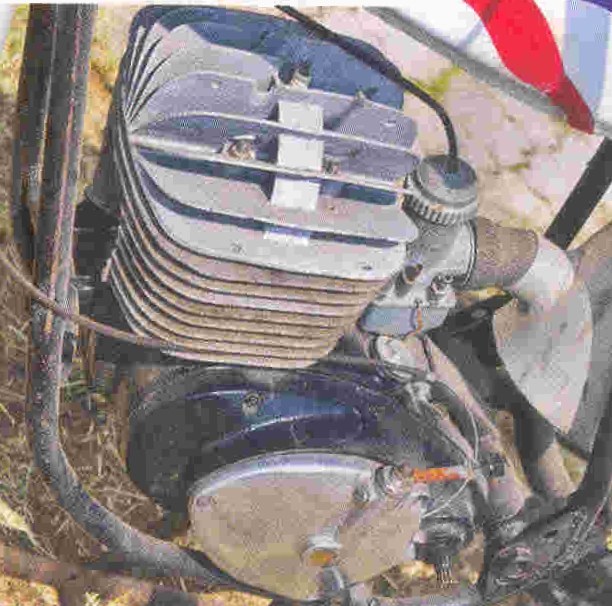

TM3 4-202 of 1973

closeup of engine TMZ 4-202

A true cross bike, made in 1973 with new coded name “TMZ 4.202″ (each figure stands for proper “class” designation, engine volume, type, etc) 175cc engine had 25hp at 9000rpm, gearbox remained same with only ratios different and “neutral” was shifted to between 1st and 2nd speeds, not motorollers’ type “N”-1-2-3-4″. Double tubes frame had the engine mounted in it, wheels 21×18″, weighing 96kg, though, further it was planned to drop weight to 85kg, like others, it only came off in small series.

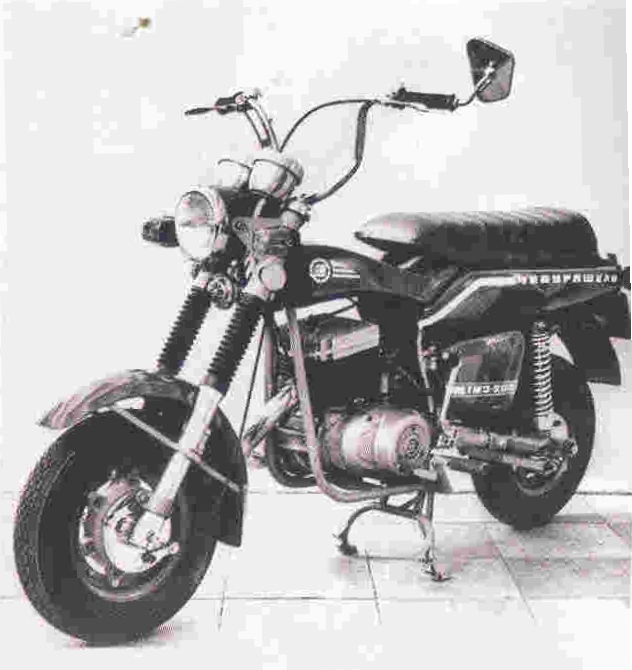

photo of a “Cheburashka” TMZ 5.306 of 1975

At the beginning of the 1970′s came a new motoroller with tyre dimensions 4,00-10″. As not to bother the factory’s red tape, the project was veiled for “motomachine” name, colloquially referred to as “Cheburashka” (a well-known Soviet cartoon animal hero with comparatively big ears-to-body dimensions- translators note). There were several samples differing in design and frame type (double tubes (duplex) or with suspended engine).

“Tulitsa”

“Tulitsa” proceeded in 1978 with not much difference in look: cast alloy wheels with steel rims and silencer shape. It’s heart was a new designed engine, aluminium jacketed with cast iron sleeve, as older solid cast pot would often seize pistons, 3-port scavenging, increased compression ratio and enforced crank-rod connection design. With 14 hp, top speed reached 97km/h.

late 1970′s Tula utility trike

“Soviet response to “Servicar” – original design trike developed in co-operation with lvov design team by end of 1970′s, small cargo room would seem not practical , but let’s remember that “sales to public” were banned “as not to multiply “entrepreneurs” (in soviet state ideology – any semiofficial retail seller).

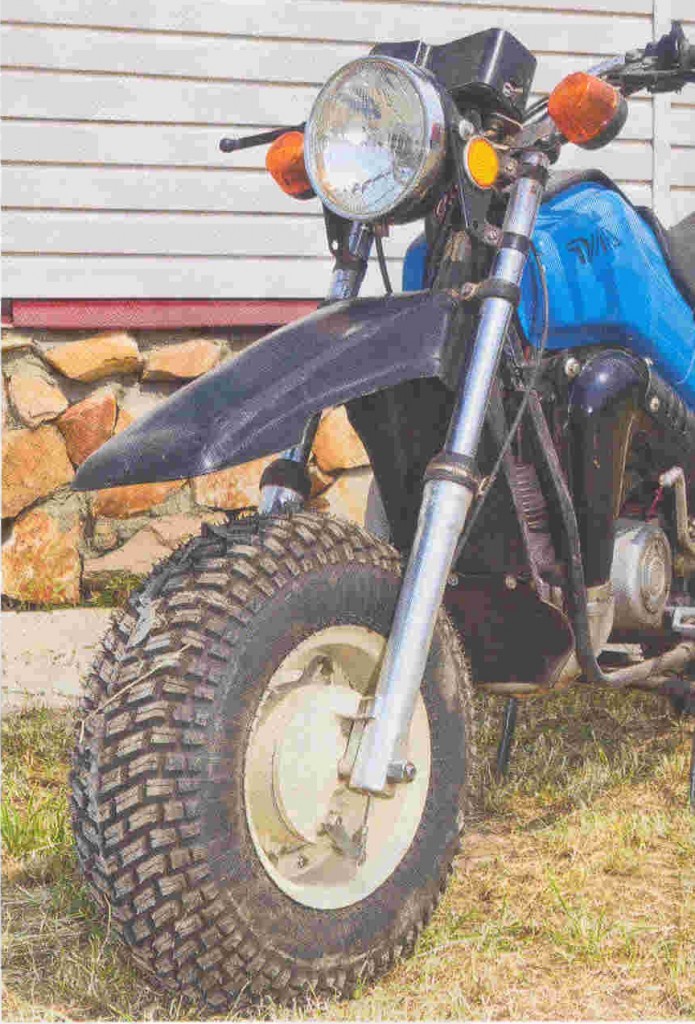

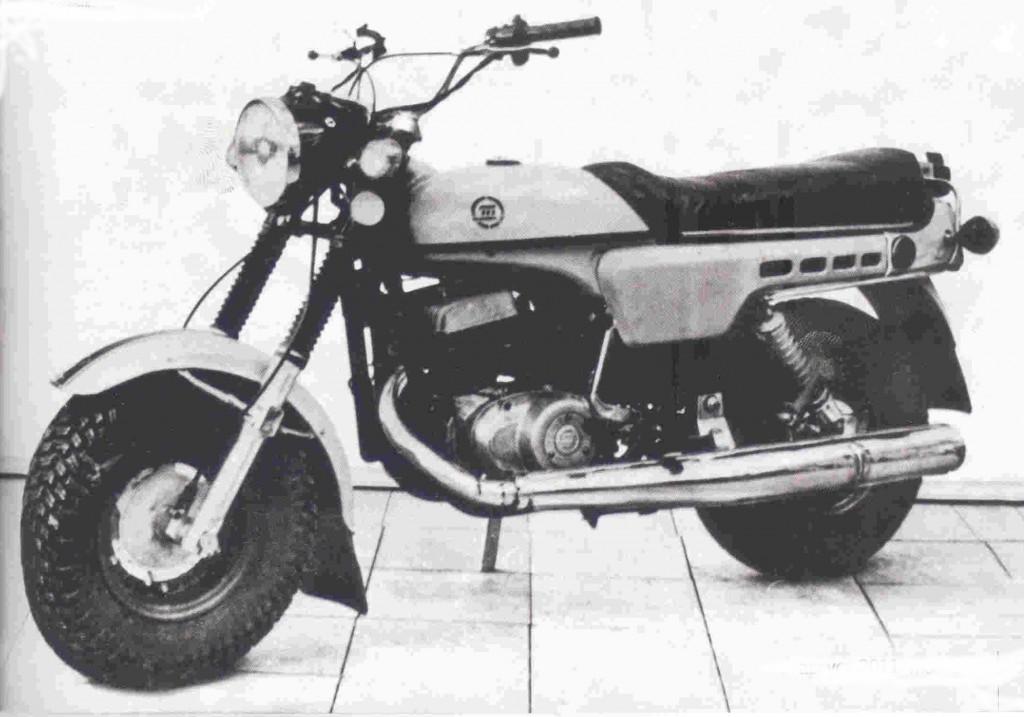

TMZ-5.951 of 1984

TMZ 5.951 – first Tula’s new motorcycle to come off conveyor, first “XP” series of 100 pieces was made in the end of 1984, mass production started in following year. Unlike prototypes, it’s engine retained dynastarter (same appliance acting as electric starter and as generator after engine is running), 1st in Soviet moto-industry to have a leaf valve installed in its cylinder, cooled by crankshaft-mounted fan. 12,5hp 85 km/h with 129 kg of weight. To add as it proved later, wide tires 6,70×10″ was no good for earthy surfaces, but on “sand” it rolled well enough.

1991 Tula trike

After motorcycle production was started, by common logic a 3-wheeled variant should follow solo version, with perfectly suitable “balloon butt” from commercial motoroller version. Picture of experimental sample, series machines produced since 1991 had different look of mudguards and cargo rear rack.

1970′s Suzuki-inspired 2nd version of “Cheburashka”

note: like to have a decent photo

At the beginning of the 1970′s Suzuki produced Van-Van (Japanese.”wow-wow”) with wide profile tires, which gave a hope for “Cheburashka” – an odd looking motorcycle with improper wheels it seemed to turn into a wanted house keeping all-road transport means, first series had road purpose outer design.

Cover of MOTO Moscow Russia 1/1991

Tulitsa’s ancestor?” – Magazine MOTO Moscow Russia article title had that in question in present edition of its very first issue of 1991. New model “Lotus” would please its owner with modern-looking coatings and cvt transmission, later tested in our edition with optimistic conclusion “the Lotus bud sprung in time”…It was destined not to come to mass production as it had been put under question. By mid 1990′s the price for the motoroller equaled that of a used car in fair condition, its fate was out of question.

Tula

.

Many thanks to Eugene Radchenko for translating this especially for b-Cozz.

(translation Rolling cars of Tula)

Additional notes:

In 1956 it was decided to release the factory scooter – a fundamentally new for the USSR a machine of this kind. In this work, the most actively involved were plant designers: A.Y. Svatenko, V.A. Zobnin, A.D. Kozin, M.B. Morgulis, Y. Moses, V.I, Pudoveev, S.S. Swim . Y.P. Osipov, and many others. The work on drawings took a very short time – just one block. All design work was carried out under the overall supervision of Chief Designer A.V. Lototskogo and direct participation of the deputy. Chief Designer L.S. Mochalina. Manufacture of parts and assemblies was requested, workshops were also engaged in the production of other products. So, in the shop number 21 produced a pilot batch of engines, shop number 24 – Part tiled in shop number 20 – crank shafts, bushings, shafts, gearboxes. At the same time the organization was started by three main workshops: № 13 – engines (early A.I. Latov), № 22 – Coil (early I.S. Kudryashov), and the number 26 – motorollernogo assembly (early V.S. Strokov). On 27 April 1957 off the assembly line came the first production scooter, and by the end of the same year they were released 992 pieces. At the end of January 1957 the newly organized shop number 26, collected the first five experienced scooter T-200 and immediately began their trials. First serial scooter T-200 was 8 hp, speed – 75 km/h, weight 160 kg. For the development of the design and introduction of a scooter “Tula” decision of the Main Committee of the USSR National Economy of 14 March 1960 was awarded to: a large silver medal Lototskii A.V. Mochalin, L.S, Zobnin, a small silver medal A.V. Ivanov, V.A. Popov, V.A. Kapkin, B.K. Prinin, I.G. Lerman, bronze medal A.I. Latov, V.S. Mironov, N.A. Frykin

- 1959 – published a series of wheel scooter specifically for the needs of communication

- 1960 – released an upgraded model scooter T-200M instead of the T-200 model. In the same year commissioned by ENEA of design double motoroller for plying the trade show.

- 1961 – went on sale a large batch of T-200K scooter with sidecar. Copyright V.I. Pudoveev.

- 1962 – published a series of wheel scooter with isothermal van for perishable products.

- 1967 – released a new model of scooter “Tourist” instead of the T-200M. Author E. Shcherbakov.

- 1969 – released an upgraded model scooter truck “Ant” instead of models TG-200K and TG-200F.

- 1973 – released game wheel scooter TGMK -200 with fiberglass cabin for the Ministry of Communications, the authors V.I. Pudoveev and I.G. Lerman.

- 1976 – April 22, was built the one-millionth scooter “Tourist”.

At this time, the scooter was no longer a novelty, although the history of the production of scooters in the enterprise begins at 1957.

When a group of young designers led by A.V. Lototskogo created the first domestic scooter class “luxury”, which received the designation T-200.

On the basis of units of scooter T-200 designers V.S. Mahonin and I.G. Lerman created the cargo scooter in two versions – with a body-200k TG and TG-200F van.

- 1977 – the serial release scooter “Tulitsa” instead of “Tourists”.

April 27, 1957. This day went down in history of our factory bright page. From the conveyor motor went first serial issue of “Tula-200.”

But the beginning of the production is always preceded by the development of product design.

In this article I am hoping for his own memory, I want to tell the story of the construction of the motoroller.

At a department chief designer, headed by A. Lototskii, early in 1956, was organized by a group of mostly young professionals, just graduated from Tula Mechanical Institute or college name Mosin. Directly supervised by the group deputy. Chief Designer L.S. Mochalin. An amateur rider himself, he picked up his aides people for the motoproject.

As experience in manufacturing these machines was not anybody in the factory, and the union of the whole motorcycle industry, it was decided to take a sample of one of the foreign models – “Goggo-200″ West German “Hans Glace.”

From the start of work on a scooter manifested, and then develop and consolidate the main feature designers Tula school – enthusiasm increased, we can say painfully heightened interest in technical innovations and their use in models produced machines.

Collective soul was A.D. Kozin – an educated engineer, a thoughtful and talented designer, well versed in engines, electrical supply nodes and chassis. In scooter “Tula-200″, he created an as yet not found in domestic or foreign practice light information on a gear, as well as the combined use of two types of engine start, duplicative, – electric starting and Kick.

In 1957, the young engineers V.S. Makhonin and I.G. Lerman developed design scooter truck “TG-200″. After a brief of its release, this model has been redone, and as such is still produced, changed only design lining, saddles, handlebars.

’33 Motoproizvodstva development can be divided into two stages.

First – from the start of production until 1980. Over the past 19 years, the plant has mastered the five models of scooters and 7 trucks. I must say that it was mastered models much less than suggested designers. Passenger scooter “Tourist” – author E.N. Scherbakov, cargo van with refrigeration compartment – author I.G. Lerman, moto-rickshaw for two passengers on request ENEA, passenger scooter with sidecar – collective work of several authors.

All models are developed, and while it is difficult to even list them.

Second period – from 1980 to the present time was marked by a more intensive development of design development. 5 versions of scooters and 12 models cargo, the all terrain bike “Tula” have been developed and put into production. New motorcycles – bike with wide tires – constructors E.D. Vlasova, A.V. Hramchenko, A.N. Balahtara and cargo module E.N. Scherbakova are in high demand in the market.

I must say that lately the better changed the look of our scooters. Great credit goes to artistic KB, led O.F. Shmelevym. New models characterized by high technical parameters, allowing them to certify to all of the highest quality.

Cargo scooter, and soon, perhaps, will be equipped cabin, for this it is modernized. The first cars produced in June.

We have to develop scooter truck “Ant-4″ cab and a diesel engine, designed for long life (80 thousand km) and large capacity (620 kg) for use in urban areas and in rural areas. This trial will begin at the end of the year.

Article from the city of “Communist” 07.09.1989g

.

E.N. Scherbakov. History Tula scooters

We apologize for the quality of the material – the article went as a scanned document, with many omissions and unreconciled scanning errors. Currently assigned article Evgeny Scherbakov (at the time – the chief designer motostroyeniya TMZ) and Evgeny Vlasov for clarification and supplement details

We would be grateful for any corrections and additions.

June 19, 1956 the Council of Ministers adopted a resolution on the organization of the defense industry factories producing fundamentally new for our country, individual mode of transport – scooters. According to the government, only from companies who can master this technique issue were Tula Instrument and Vyatsko – Polyansky OMZ. The corresponding order of the Ministry released July 7, 1956. It instructed the Tula Engineering Plant master production cars scooter with an engine capacity of 199 cm3 and the end of the year to release 2.5 thousand scooters, and the next 1957. increase production to 30 thousand (Vyatskie Polanski plant was to begin production of passenger scooter class 150 cm3). Prototype cars scooter plant was proposed West-scooter “Goggo-200″ company HANS-iced. In appearance, technical parameters and some advanced design solutions of scooters 1950 1955gg. he was the only solid sample. Power 2-stroke engine 9l.s., maximum speed 80 km / h, trunk, spare tire, <…> in the dashboard, monotube shocks with constant resistance characteristic, aluminum cylinder engine with chrome mirror, electric starter, with chopper centrifugal regulator ignition timing benzokranom remote control, removable and lockable seat, anti-theft locking steering headlamp with adjustable driver’s seat, glove hook on board, convenient access to all nodes through removable hood sides, good protection of the driver and passengers – this is not a complete list of the benefits of the prototype.

Until the end of 1956, a full copy “Goggo-200″ have been developed on the vehicle-part drawings. Design work was carried out under the supervision of chief designer of the plant A.V.Lototskogo, with the active participation L.S.Mochalina, V.A.Poluhinoy, V.A.Zobnina, A.D.Kozina, A.Ya.Svatenkova, M. V.Morgulisa etc. Since experience in designing 2-stroke internal combustion engines at the plant was not the development of design documentation for the engine (actually the engine, clutch, transmission changes gears, cooling system, ignition system) conducted by specialists TSKEB mototsikletostroeniya (now VNIImotoprom ) under the leadership of V.V.Rogozhina, with the active participation of designers A.K.Bahshetsyants, S.Yu.Ivanitskogo, I.V.Kazanskogo, N.P.Polyakova etc.

Earlier Soviet industry scooters are not made. A large volume of production of working drawings and assemblies scooter, process design, engineering and manufacturing of equipment, delay in delivery of the purchased units and parts are not allowed in this year to start their production. In addition, workshops were not identified by serial production of scooters, so to organizing workshops motoproizvodstva major parts and components manufactured the scooter shop number 21, crankshafts and transmission parts – shop number 20, facing parts are handmade in the shop number 24, the details of the vehicle- (frame, lining, steering fork, etc.) produced in the shop number 22 (foreman Pronin BK). In these shops to the top in 1957 were made 5 passenger scooter T-200 and began extensive tests.

First serial scooter T-200 rolled out in the shop number 26 April 27, 1957, and May Day demonstration in 1957 was attended by five mass produced scooters T-200. However, despite the start of series production, the plan for the production of cars and scooters was disrupted in 1957, instead of 10,000 under the plan produced only 602 scooter T-200). For the development of the design and introduction of passenger scooter T-200 Resolution of the main committee ENEA in 1960 11 employees of the plant were awarded silver and bronze medals ENEA, including chief designer A.V.Lototsky, chief engineer of the LS Mochalin, chief technologist AVIvanov, Head motoproizvodstva B.K.Pronin, foreman A.I.Latov. Plant for the work was awarded the diploma of III degree ENEA. Given the need of the economy in the form of easy and economical freight transport, the chief designer of the plant constructor A.V.Lototsky instructed WGC V.S.Mahoninu I.G.Lermanu and develop cargo scooter using assemblies and parts cars scooter T-200. In project work, except V.S.Mahonina and I.G.Lermana participated A.I.Schekin. In early 1957 the first samples scooter truck TG-200 were manufactured and began a road test. In the prototypes and then in mass production – 3000 pcs. – Used to output nodes of Serpukhov wheelchair buggy: differential and balancers. Van manufactured the Tula Combine Plant, front shield with decking, cover the front wheel, front wheel brakes, electrics and engine muffler used cars scooter with T-200. When tested scooter truck there is a need, except for the electric starter, have an understudy – Kick, it has developed designer I.G.Lerman.Kick the same in the future and was introduced on passenger scooter T-200.

Cargo scooter TG-200 put into production in late 1957 and in early 1959 approved the mass production of the expert council Chamber of Commerce of the USSR. For the development of design scooter truck TG-200 plant employees first A.V.Lototskomu, L.S.Mochalinu, V.A.Zobninu, I.G.Lermanu and VS Manohina was awarded the laureates of.SI Mosin.

On the basis of the scooter TG-200 were developed and mastered the production of its modification-trailers and trailers isothermal TG-200F and TG-200I. For the development of the design and introduction of wheel scooter with isothermal van plant in 1962 was awarded a diploma ENEA. Decision of Chief Engineer I.G.Lerman ENEA Committee was awarded the large silver medal, and the engineer and mechanic A.I.Schekin K.A.Seregin – bronze medals. The first production motor freight TG-200 had the following technical data: 2-stroke engine, the working volume 199 cm3, power 6 hp (?) Capacity 200 kg, maximum speed 50 km / h, fuel consumption per 100 km. – 5.5 liters. weight 265 kg (with body) and 310 kg (with trailers). Freight motor TG-200 from the beginning of production, before withdrawing from the production were very popular, and since the beginning of the 60s in a lot of them have started to export. It was a good and much needed trucks.

Passenger scooter T-200 liked consumer – good occupant protection from dust and dirt, convenient and reliable electric starter to start the engine and Kick, forced air cooling of the engine, the availability of the spare wheel, the presence of the light pointer speed, powerful headlight, providing good road illumination, convenient access to major components for maintenance scooter. These positive qualities cars scooter T-200 immediately took advantage of designers to create new vehicles.

In 1960, the designer and chief designer I.G.Lerman TSKEB mototsikletostroeniya A.T.Volkov based on passenger scooter T-200 developed by ENEA design mototaksi order to transport visitors to the exhibition. 50 pieces were produced and they operated until the trains.

(Ed., According to our data, the plant Vyatskie Glade was also produced 50 “rickshaws” )

In the same year Chief KB promising developments VI Pudoveevym of design side Trailers for passenger motor scooter T-200. Manufactured prototypes were subjected to road tests. The tests revealed a number of serious shortcomings cars scooter, which joined the side trailer – low strength frame, poor driveability, lack of strength steering fork and front wheel suspension, low durability chain final drive. The resulting improvements vehicle-parts and steering fork cars scooter T-200 eliminated the shortcomings that tests confirmed: durability steering fork increased 10-fold, 2.5-fold frame.

In <…>, it was made <…> pieces scooter with sidecar and sold through the trading network. But for the serial production was no production capacity and therefore production side of the trailer was not organized. However, a modified passenger scooter was put into series production in 1962 under the T-200M. He was pulling the front suspension design type and V.I.Lopuhina V.I.Pudoveevym modified for mass production, easy shock absorber front and rear suspension, the oil bath vozduhofiltr Yu.P.Pozdnyakova design, hardened frame and other changes. This passenger scooter manufactured before 1968 goda.Vse changes raises product passenger scooter immediately implemented and cargo scooter TG-200.

To expand consumer qualities cars scooter T-200 and T-200M V.I.Pudoveevym was designed rear trailer that could be operated with a motorcycle and a passenger car.However, due to lack of production capacity, he was not put on production. For the same reason he came to the consumer easy electricians, light due to new forms of elegant tiled passenger scooter “Meteor” design A.D.Kozina. Besides the disadvantages of the vehicle-passenger scooter T-200 in the process of testing and operation of the consumer have been identified shortcomings of the engine. West German motor scooter “Goggo-200″ had a capacity 9l.s. first scooter engines of our T-200 only 6 hp. Used mesh vozduhofiltr did not provide good air purification in our road dusty conditions and therefore there was a large depreciation of the cylinder group. Therefore, since the beginning of the production team of designers, researchers and metallurgists (A.D.Kozin, V.I.Pudoveev, L.F.Boyarnikov, Yu.P.Pozdnyakov, VY seals A.A.Lomakin) worked to improve engine power and durability of the cylinder, piston and piston rings. Hydrodynamics has been changed by passageways and shape of the combustion chamber, introduced the method of cast iron cylinder shell casting, introduced oil-inertial vozduhofiltr Yu.P.Pozdnyakova design. This allowed to increase capacity up to 9 HP and to reduce fuel consumption by 15%.Increased engine power has led to increased load on the connecting rod bearing and the clutch. On the proposal was introduced A.I.Balahtara designer Ming connecting rod bearing, and on the recommendation of A.D.Kozina increased number of disks in the clutch with <…> to <…>, which ensured the transfer of high torque. Further work on improving the design of the engine have been associated with the emergence of new proposals for passenger cars and commercial structures scooters. Good, strong demand for cars and trucks scooters, as well as the job of the Ministry to increase output and improve the quality of the models set ourselves the task of improving the plant’s management capacity motoproizvodstva, the introduction of new high-performance equipment, new advanced technologies, new designs of parts and components that reduce the complexity of manufacturing without impairing the consumer qualities.Technical re motoproizvodstva this time was led by the chief engineer of the plant L.S.Mochalina, deputy of the Supreme Soviet of the USSR, which enjoys great prestige among the city authorities and the ministry’s leadership and went on several fronts: – organizational and personnel policy – from Irbitskogo motorcycle college were selected most achievers graduates and taken to the factory (L.F.Boyarnikov, A.P.Karpov, V.Ya.Tyulenev, E.F.Pozdnyakova <…> to establish close ties with the country’s only research center-TSKEB mototsikletostroeniya g . Serpukhov (Rogozhin director VV)

Given the importance of the work on improving the design of scooters and the responsibility for it at the end of the 50s in the department chief designer were organized motoproizvodstva design bureau (bureau chief V.A.Zobnin). Advanced engineering design bureau (bureau chief V.I.Pudoveev). Cash-Analytical Bureau (Chief T.V.Gromova), and on the basis of expert machine tool area organized experimental plot motorcycle and machine-tool (senior master I.G.Arhipov). Was appointed chief motoproizvodstva B.K.Pronin, formerly chief of the vehicle-shop number 22. To ensure the stability of the plan of passenger scooter T-200, TG-wheel scooter 200 and spares them were finally established guilds motoproizvodstva. Launched in 1957, the organization of workshops motoproizvodstva ended the first phase to 1960. – Is the production engine scooters – shop number 13, first chief of the shop was an experienced organizer A.I.Latov production, which was soon replaced by S.V.Cheverov and A.I.Latova appointed head of department number 42 for the production of the most critical parts of the engine – crankcases, crankshafts and sophisticated suspension damper assembly scooter. The assembly shop number 26, was appointed as an intern – a graduate of Tula Mechanical Institute V.S.Strokov. To carry out a road test to check the quality of products in the shop number 26 was organized by laboratory testing on the road and customer service on the claim. Was appointed head of the laboratory <…>.

Following the appointment of the chief B.K.Pronina motorcycle veloproizvodstva appointed?.?. Kudryashov. Technical equipment due to the introduction of new equipment, advanced technological processes allowed the 60-ies of the program to ensure the stable high quality of manufacturing (percentage of claims was the lowest compared to other Motoplant).

When prosperous position in the factory for the production of cars and trucks scooters were two disturbing circumstances for future development motoproizvodstva – a state of punching parts and facing the prospect of stay on the market passenger scooters T-200 and T-200M with the technical parameters that they had on that period. To this must be added the high complexity of manufacturing units and parts trucks and scooter.

Plot facing manufacturing was on the territory of the forgery consisted of <…> presses (tightness and no organization of production). Deep drawing dies were designed and manufactured at the Dnepropetrovsk plant, as at the Tula factory was no specialist on the design of stamps, nor the experience of their production. With such a state of stamping production could not think of any statement on the production of new models, or to increase the output of existing models. Besides the van continued to produce at the Tula Combine Plant.

Chief Engineer L.S.Mochalin in early 60s under the pretext of expanding production offshore installations received permission and funding for the construction of housing for the manufacturing and assembly facilities and accommodation in this building stamping (shop number 1 and shop number 35).

This housing was built on the site of the factory and the park was commissioned in 1964. Difficult situation has developed with promising model cars scooter. In May 1960 the factory in WGC for a permanent job came from CDB-14 E.N.Scherbakov engineer with project cars scooter. Proposed the following technical parameters scooter:

- Volume 2-stroke single cylinder engine 250 cm3.

- Transmission – V-belt type CVT available in the OGC sample scooter DKW “Hobby” (Germany)

- Engine with transmission up the rear wheel suspension (swinging engine) type scooter “Lambretta” (Italy)

- Suspension front wheel push-type (similar to BMW motorcycle Germany)

- Shock absorbers Pneumohydraulic setting up the force depending on the load (by pumping)

- Wheel or tire size 14×4 <…> x3, 25 (motorcycle “Sunrise”, the Carpet)

- Facing Heinkel scooter-type “Tourist” (Germany) with the presence of internal and external trunks.

The project was discussed at a meeting with the chief engineer L.S.Mochalina, attended by chief designer A.V.Lototsky, head of OTC N.G.Karelin, Deputy. V.A.Kapkin chief technologist and head of KB V.A.Zobnin.

At the meeting it was decided that the project is characterized by originality and development of a distant prospect, but adopted for implementation can not be for the following reasons: – there is no proposal for a unified passenger scooter wheel scooter (as is the case with the T-200 and TG-200) factory can not master the production of a new engine on the existing areas simultaneously with the release of the motor scooters for T-200 and TG-200.

It was recommended to develop a project E.N.Scherbakovu passenger scooter with an engine of 250 cm3 class ensuring the possibility of creating scooter truck-based cars, and with a maximum unification of purchased and other components and parts manufactured passenger scooter with T-200.

This project was carried out prior to 1961. The general layout of the scooter and the implementation of the prototype of a 1:1 scale clay spent E.N.Scherbakov helped him V.N.Romanov (International Master of Sports in cycling), E.D.Simutin, E.F.Pozdnyakov , L.A.Volkova, N.V.Podemschikova.

In 1961 he was made a prototype, but with the motor scooter T-200, as the 250 cm3 engine class was not yet.

After the pre-test new passenger scooter (the name “Dolphin”) the technical council of the plant was decided to continue the work on the creation of a full passenger scooter T-250.

In early 1962 the technical council TSKEB mototsikletostroeniya draft was reviewed and approved by the direction taken.

On the technical council of the plant in Serpukhov attended L.S.Mochalin chief engineer, chief designer A.V.Lototsky, Head KB V.A.Zobnin, Head of Laboratory A.A.Lomakin, design engineer first category E. N.Scherbakov.

Report of the construction of a new passenger scooter T-250 make E.N.Scherbakovu trusted. This practice – the report made by the author of the project – to plant remained at 90s.

In 1963, the first engines were made of 247 cm3. Author of the project – Yu.P.Pozdnyakov laid in advanced engine design known solutions best foreign engines. On the creation of a domestic engine class 250 cm3 with Yu.P.Pozdnyakovym worked: L.F.Boyarnikov, V.I.Lopuhin, <…>

In 1964 ended developmental testing engine, by this time part of the vehicle-passenger scooter passed all the tests – strength, steering and stability, smooth running, for ease of maintenance, etc.

The first prototype passenger scooter T-250 with 2-stroke engine of 247 cm3 and 18l.s was assembled in <…>. year, began testing the scooter at full strength.

In 1964, the plant’s management, it was decided to manufacture cars staged scooter with a 2-stroke engine of 250 cm3 and 18hp without discontinuation of passenger scooter T-200M and scooter truck TG-200. To start the production of new cars scooter needed a major reconstruction motoproizvodstva. For this purpose, an agreement was concluded with MPKTI (interdisciplinary Design and Technological Institute of Tula) for technology development, design and production of proposals for the reconstruction of shops. Chief engineer of the project was appointed I.H.Vakeman.

Together with the technical services of the plant has developed a comprehensive plan for technology, advanced equipment, mechanized conveyors as storerooms and intrashop and interplant.

Was scheduled for the first phase of reconstruction of workshops – the vehicle-number 22 and number 26 of the assembly shop with a line color. And all this was done for cars scooter primarily for the new model.

What has caused so much concern about the fate of cars scooter?

· First, the production of passenger scooter is almost 2 times higher than the motor freight.

· Second, motor freight to <…>, the population is not sold and distributed only by organizations, so the demand for them was guaranteed for many years to come, and competitors wheel scooter Tula production on the domestic market was not.

· Third, the cars were serious competitors scooter – motorcycle class 125, 175 and 350 cm3 (Minsk, Kovrov Izhevsk) and demand depending on the technical level cars scooter than a motorcycle.

· Fourth, motor cars and motorcycles existed guests on technical parameters, and quite rigid requirements were at the level of world standards (for cargo scooter that guests were not), so the need to improve passenger scooter was constantly due to these guests.

Passenger scooter class 250 cm3 had technical parameters from a distant prospect of preparing a draft scooter truck-based passenger allowed to reach a qualitative model of the truck load capacity (load 500 kg., Instead of 200 kg. The scooter TG-200).

In 196? he was made the first commercial batch of 50 pieces of passenger scooter with an engine 250sm3 engine power 18l.s, maximum speed 100 km / h.

For the manufacture of parts facing the Gorky Automobile Plant were made plastic molds for deep drawing.

But none of the scooter 50 pieces were sold to the public for one reason: the existing structure dinostartera DS-1 did not provide a reliable start of the new engine. To address this shortcoming immediately began work at the Research Institute to create a new motoprom dinostartera.

Made scooters were used for participation in the trial championship factory brand, multi-day events at the USSR championship, in different kinds of advertising runs through the territory of the Soviet Union. All these tests and competitions showed high durability nodes scooter, good smoothness and ease of operation, low maintenance fuel consumption – 3.2 hp 100 km.

Way to produce perfect, perspective, cars scooter class 250 cm3 was opened: and the beginning of reconstruction motoproizvodstva, and began reconstruction motoproizvostva and fabrication of tooling and equipment. Minsk Plant of modular machine tools in 1966 put 15 modular machine tools for processing parts of the engine crankcase, 2 machines for processing pendulum steering fork and swingarm, shop number 25 made multihead machines for machining holes in the frame of the scooter cars. Toolmaking manufactured molds for die-cast aluminum engine parts and the main gear, molds for plastic parts vozduhofiltra, steel molds for investment casting, etc. In addition, for the installation of equipment and the organization of production of the new engine without stopping production motor scooter T-200 were released production area due to the transfer of production of child bicycle Schekinskie colony, where he was appointed head of production Drums C.

Serial production of the T-250 scooter and has not begun. Suddenly, the decision of the Ministry of factory plant was ordered to organize the production of self-propelled anti-aircraft complex “Shilka” with 4 cannons design N.M.Afanaseva (caliber 23 mm with liquid cooling), so production area vacated for production of the new engine were transferred 250sm3 under development “Shilka” and the new passenger scooter T-250 with a modern engine, unfortunately, did not reach the consumer.

In this situation, the chief engineer V.S.Usov made a bold decision: to continue the reconstruction motoproizvodstva and designers to install the engine passenger scooter T-200M passenger scooter design on T-250M, increasing its capacity to 11 hp For three months this work is performed. In May 1965, Hrachia drawings were sent to the unit to the factory pre-production cars scooter T-250/200 – part of the vehicle-passenger scooter T-250, a modified engine for the T-200.

Supervised the work of the chief KB passenger scooter E.N.Scherbakov, actively participated A.Nikitsky, V.Barnar, E.Simutin, E.Pozdnyakova,?. Amelin and others 1965.factory team on passenger scooter T-250/200 “Tourist” has participated in international motoralli USSR-FRG and took first place in the class scooters. Name the new motor scooter T-250/200 E.Vlasov offered and it was accepted. In USSR run FRG appeared high level of vibration to the steering wheel and on the bottom of the tank, leading to breakage tank.In 1965 and 1966-ies. conducted research on the possibility of reducing the vibration to acceptable values as their effect on the driver, and the durability of vehicle-parts. The solution was found: soft mount the gas tank, fuel tank capacity is reduced (to 12, 5l.) Redistributed weight to the frame and a scooter in some places has introduced strict headscarf. By May 1966 a full set of drawings with all modifications was finally transferred to the service of the plant for pre-production cars scooter “Tourist”.

To commemorate the 50th anniversary of the October Revolution began production cars scooter “Tourist” to the end of 1967. 300 pieces were produced, but then production was halted, thus revealed shortcomings that should not have taken place in mass production.

In tests of prototypes cars scooter aluminum wheel manufactured by injection into the ground, and when large-scale production – injection molding, which led to a decrease in the walls and increase the porosity and strength, respectively. After completion of the construction and correction of molds for injection molding production cars scooter “Tourist” with the new wheel began in March 1968 and continued in various upgrades until 1987 – 19 years passenger scooter T-250/200 pleased consumers of all ages.

For the development of construction and putting into production cars scooter T-250/200 “Tourist” group composed of factory workers I.Arkhipova (Deputy. Engineer motoproizvodstvu) V.Barkara (early KB passenger scooter) V.Dublenskogo ( Deputy. Chief TOMOTO) A.Lomakina (Head of Design – Research Division reliability) and E.Scherbakova (author of the project T-250/200, zam.gl. designer motoproizvodstva) in 1968 was awarded to them. SIMosin. Along with perfecting the design and introducing into production cars scooter “Tourist”, worked to improve the scooter truck TG-200 in order to reduce the complexity of manufacturing and improve the reliability and durability of the basic units.

In 1959, the bureau chief planning stages V.Pudoveev changed the construction of the differential – instead introduced a gear chain transmission, which greatly increased durability node. Later, he also proposed a simplified structure frame scooter truck, changing the principle of chain tension ratio: instead of tension by putting spacers between the engine and the frame suggested tension by moving the differential (cycling type), which greatly facilitates maintenance scooter truck TG-200 and improved the quality of regulation. Simultaneously with this, instead of springs in the balancers (two pieces for each side), it was suggested only two (one on each side). In addition to these changes, in order to reduce costs, have been introduced rubber-metal bearing universal joints instead. Since introducing into production cars scooter T-250/200 “Tourist”, in early 1969 began to produce scooter truck TGA-200, developed by a group of designers led by V.I.Lopuhina.

Cargo scooter was unified with “tourist” sites: engine, steering fork front suspension and wheel, steering, electrical system, exhaust system, front shield with decking and cover the front wheel and the other nodes. However, during the operation of the consumer became necessary change the steering and front suspension stiffness while maintaining borrowing parts from scooter cars “Tourist”. In different versions of this cargo scooter was produced until 1985, only 562,000 were produced such machines.

After the organization of production cars scooter “Tourist” and scooter truck TGA-200 further work was done to improve the design, quality and the creation of fundamentally new products. In order to improve the parameters of passenger scooter “Tourist” (speed and fuel consumption) establish a more powerful engine that provided the increase maximum speed of 90 km / h. Such passenger motor scooter manufactured in 1974 under the symbol “Tourist-M.” This modification scooter, except the engine with increased power, have been introduced and other innovations: a tool box moved from the front cover under the seat above the engine frame is reinforced in the area of the rear axle of the pendulum, simplified mount hood in front of the other and

All the work on modernization held under the leadership E.N.Scherbakova. – Chief Designer. For increasing capacity and economic parameters of the engine scooter in 1975 were awarded the prize. SI Mosin: V.Lopuhin, L.Boyarnikov, N.Avilov, Yu.Pozdnyakov, P.Uymin, Tyulenev, A.Lomakin and V.Shashkov.

Improved engine was installed in 1974 and cargo scooter TGA 200. One of the factors which determine consumer demand, is the perfection of appearance and ease of use in various weather and climatic conditions. Therefore, to improve the appearance of the cars scooter designers have worked constantly and on a cargo scooter, which began selling a 197? year through the trading network of the population, consumers expressed the desire to have a cabin for possible exploitation scooter truck at any time, regardless of weather conditions. In 1960 the first prototype folding cockpit of a soft material was proposed bureau chief of the planning stage VI Pudoveevym. He then designed a more perfect metal cabin. In 196? he was made a prototype, tested with positive results, but the release of the cockpit was not organized because of the lack of production capacity, despite the fact that the stamps were made on the basic details of the cab. In 19?? <…> In the department of plastic, where the chief at the time was V.I.Pudoveev – author of the first cabin. These fiberglass cabins were installed on truck chassis scooter and sell it to consumers (mainly organizations) mail, factories, retail outlets, etc. Development of design documentation fiberglass cab was led by Chief KB I.G.Lermana body, and a group of designers: Belov, O.Neznanova, Navumau, M.Penkov etc. Mass of fiberglass cabin it was not because of the high cost products in general. The next step in building a cabin for cargo scooter was a joint development Minsk Branch VNIITE and design department MOTO Tula Engineering Plant. It was a cabin frame type with ABS plastic, which meets all the requirements for vehicles with cabin. In 1989 and in 1990. been made of 50 pieces wheel scooter with this unit. In preparation involved: I.Lerman, M.Pelnov, O.Neznanova, Navumau, Belov under the leadership of Chief Designer Komoto V.I.Pudoveeva.

Perestroika 90s are not allowed to go for serial production of the cabin, but is currently on the road and the Tula region Minsk operated plastic cockpit design. To increase the demand for freight motor V.S.Usovym was proposed design 2-seater scooter truck, construction documentation which developed KB-wheel scooter, led by Dr.Yu.P.Pozdnyakovym. Double cargo scooter with a 19?? , the mass manufactured before production ceased scooters at all. Small batches at different times produced motor freight with a body dump (authors and A.Bochkov Pudoveev VI), with awning (authors E.Vorontsov, N.Burchihina).

In order to reduce transport costs in the <…> year was proposed and implemented original scheme bunk shipment wheel scooter. The proposal has V.I.Pudoveev, V.S.Zimin, M.A.Malevsky T.P.Lifanova developed design and installation of loading scooters in two tiers: one scooter was fastened on the other. In this invention obtained a patent. For easy driver protection from the weather and headwind for freight and passenger motor scooters from 1960 to stop production of scooters manufactured removable wind shield. It comes in a sale separately and in great demand among motorcyclists. Cargo scooter has always enjoyed good demand in the international market, and to expand the supply of expert in the year 1989-1991 was carried out work to create documentation for assembly groups Kits cargo scooter and motorcycle parts for companies in Mexico, Colombia, Argentina. Supervised the work of an experienced chief of bureau E.I.Gololobov. Sending Group products kits will significantly reduce the costs of transportation of exported motorcycles. Total number of vehicles sent to recipients compiled 12,868 products.

.

Uimin Petro (Komoto)

“In the early eighties several years stood out dry. The farmers could not feed a herd of cows to feed and had to cut even shrubs. In the “top” was decided obkashivat all the surrounding villages and roads, so-called “Rough open.” This required “strong fellows” of the cities. To facilitate their work, the company decided to develop a walk-behind miniselhozmasha including in the unit with mowing. For these purposes could be used scooter engine having a forced air cooling. Several consumer-wheel scooter sent to the factory pictures adapted for farming their ideas. And then in CO motorcycle appeared to try to create the idea of units and parts scooter behind tractor. I, a native of the village, liked the idea. Using the experience of the designers, the factory name Ukhtomskii Lyuberets and avenues of power tillers from Italy and Japan, I painted over the winter months their offspring, and by the summer it is manufactured in the shop number 40.Required test. Mower, and Pluk pochvorezka were brought from Lyuberets. With the mower, he worked not bad, but when plowing out of order worm pair in the transmission.Tried to use walk-behind and to the needs of the factory. In particular, the tow truck to transport scooters through the plant. But this was not enough engine power and load wheels for reliable traction.

Without releasing behind tractor parts made no sense, but in the USSR were never produced. And then it was decided to design mowers. To accelerate manufacturing was selected with a rotary cutter body. Again the design work conducted in the winter and worked O.F.Shmelev appearance. Top of haymaking was made five cars. Tests were carried out on the farm “Rodina” Chernsky district. When tests revealed poor performance due to low width and greater danger from rotating masses at speeds up to 2000 rev / min.

By that time, were purchased in Italy behind tractor company “Goldani” with a set of mounted units and the Czech Motor mower “Terra”.

Food Programme in the USSR forced plants do release small art more seriously. On MASHZAVOD was decided by KO Moto (walk-behind himself) and cutting body design walk-behind mower with a unit suitable for commercial production at the plant.

Motoblock accelerated methods designed office staff-wheel scooter and the cutting body (based on cutting body was taken by “Goldong” developed in Komoto office staff Linovskiy AE) Force workshops 25,18, 39 and 40 were produced about 100 motokosilok that were assigned to units mowers and sent to Chern district for farming. But all the difficulties of operating motokosilok were connected and their servicing. Needed vehicles for delivery to the place of work and back, required special containers for the storage of petrol and oil.Besides required daily inspection of the cutting unit. Seized almost nobody wanted. Three years later, this saga is over itself. And after took up the job factories of the Ministry of the aviation industry and has commercialized tillers.

Once freight motor started selling to private traders, the factory went letter requests and suggestions to protect the driver from precipitation, wind and dirt. All of these requests can be met by installing cargo cabin scooter. With the installation of the cabin was significantly increased weight of the scooter, and as a consequence, it was necessary to increase the reliability of transmission and brake system.

The factory was decided to design a cargo scooter with 2-seater cabin with hydraulic brakes and steering automobile type. Work was assigned to KB-wheel scooter headed Yu.P.Pozdnyakovym. Progress was monitored personally deputy chief of Lopukhin VI

Experience in creating. Microcar, no one was. Especially task was not out of the category A, ie ultimately it must be cargo scooter.

The basic sources of information were the Italian «APEcar», Japanese “Daihatsu” and Serpukhovskaya wheelchair. I got into designing the chassis, and Maksimov – cab and body. Frankly, to create a new model of collective clearly small. If the chassis and body on the dates you managed to make drawings, the cabin Maximov using P.M.Seregina wonderful locksmith shop in 40 brewed locally, that is called “strictly on the eye.” The result is a “home-made” without signs of design. For design using VNIIITE Moscow sent us in Baku branch. Designer VA Mageramova (in my opinion) was offered a very good option cabin, later made of fiberglass.

Was parallel refinement of the chassis. And in the design of the frame took a personal interest V.I.Lopuhin. For road test sample was made 2. According to test results had a lot of comments. Yes, and it could not be otherwise. The group was small and inexperienced.Basically, in turn, were connected to this work young professionals Maksimov, Azovtsev, Eroshkin, Teals, Pronin, Corzine. Flour creativity haunted Deputy Head of the new technique V.I.Lopuhinu. Instead of focusing resources and effort on completion of the Baku cab option, it enters into a contract for the new development with the Minsk branch VNIITE (Performer Yu.Zhutyaev). But in Minsk on business prototypes did not.

This was followed by the collapse of the USSR. I became seriously ill. Young professionals went to find where the best. And scooter truck cab was not just anyone do it.

V.I.Lopuhin tried to connect to the design department of “Cars” Tula Polytechnic Institute, but they did not have a decent level of experts.

So Tula Engineering Plant entered into the 21st century without promising developments.

Gololobov Evgeny. (Komoto)

Engine / / / based on the engine (Ed.) / / / Scooter “Goggo-200″, had a capacity of only 6l.s. that had very little to operate motoizdely the wider area of the former USSR.Therefore, from the beginning of production of scooters work was carried out to increase the cardinality and dynamic indications engines. Work was carried out in two directions by improving the gas dynamics iron cylinder production engine.

Team of engineers and researchers (A. Kozin, Boyarnikov L. Pozdnjakov Yu, A. Lomakin, V. Tyulenev) managed to increase power production engine almost doubled – to 11 hp, somewhere to 1970godu. Parallel Pozdnyakov Yu drafted T-250 engine with a displacement of 250 cm3 and bimetallic cylinder. The project has been very promising for many years ahead, prototypes showed excellent traction and dynamic performance and reliability. Unfortunately, the production area, intended for implementation in production of engine T-250 were transferred to arms production and the project was closed. At the same time under the leadership Pozdnjakova Yu were the development of projects and other interesting engines: twin engine T-400 with admission control spool (Designer V. Pavlov), automatic transmission with hydraulic shock absorbers. (Designer Gololobov E.) Despite the positive results of the tests prototypes of projects have also been closed due to unsolvable technological and economic problems if implemented.

Closing a project T-250 engines made KB throw all efforts to modernize production engine T-200. The fact that the increase in capacities up 11hp sharply reduced the reliability and durability of the engine. Have become quite common defects in operation klineniya cylinder-piston group, klineniya low crosshead bearing, clutch slippage, wear of the cylinder-piston group due to poor air purification oil vozduhofiltrom.

Therefore, under the leadership of Yu Pozdnjakova between 1971. by 1978. developed and tested significantly modernized T-200A engine with new intake and exhaust systems.New bimetallic cylinder (Parfenov E.), a new reinforced clutch (Parfenov E., Titov L), crankshaft bearing ringed (Balahtar A.) vozduhofiltr with paper element (Gololobov E, Yu Volkov), new modern exhaust system (Nishanov A.). Provide the engine high power, high reliability and durability. A huge role in the development of complex qualitative and played hard work of researchers and testers Kioni led by A. Lomakin and Tuleneva B. Implementation of the engine and systems were very hard, was too great amount of change in the production and kalibrovoy snap to learn new processes. The main burden fell on the technology department under the leadership of VD Dublenskogo and A. Seidman, under the leadership of the department metallurgist Drutmana B., plastics department under the leadership of VI Pudoveeva In addition, the preparation of the new engine has significantly upgraded and motoizdeliya themselves and by the time of introduction into the production engine to prepare the development of new products: passenger scooter “Ant.” In 1979 he 1978. These items have been fully put into production. Perhaps, these products have been the most successful, differing high dynamic performance, reliability and durability. No wonder they are now uncommon on the roads and even in the movies, although it has since gone for 25 years.

However, life is never haunted and challenges. Beginning with 1980goda, got problem significant reduction in fuel consumption and reduce vehicle emissions. Having conducted extensive research work involving VNIIMOTOproma (Serpukhov), Vladimir Polytechnic Institute.

KB engines led by EI Gololobova by 1984, drafted two engines with petal valve inlet: cargo with full-flow valve (lead designer – Pleshanov A. and cars with chastichnopotochnym valve – leading designer Balahtar AI). On these engines were reversed cylinder-piston groups, gearbox and exhaust system. Coupled with carefully selected new carburetor changes yielded high efficiency, low toxicity products by a wide margin on the required standards.

In 1985, new motoizdeliya that meet all the requirements of GOST reliability and toxicity have been put into mass production. Until the 90s KB engine was working hard to develop new engine versions: the development of a mathematical model of gas dynamics engine – Platonov N., 5-speed gearbox – N. Platonov, separate lubrication system – EE Parfengvetc.

Since 1989 KB engines start big and serious development of the diesel engine, designed and implemented in the production of new lovely starter-generator and contactless electronic ignition system. However, as I in 1989. “Washed out” on the edge of the land, of Colombia, this is better can tell Pleshanov AN Platonov and NL, for they were and organizers and leaders of these works. And then came what happened …

a Tula “stinkwheel” in military camo. Quite a handy little vehicle!

Robbie Shergold (Chunk) spent years restoring a 3-wheeled Tula “Muravey” from a rusted wreck into the best little campervan Tula could ever have dreamt of. Well done Chunk! A true labour of love. And now probably the best known Tula in the world.

From this…

To THIS!!!! Well done Robbie!

The Tula scooters proved popular with tourists and locals alike, but the 3-wheeled workhorses of cargo and utility sure did their fair share also.

Sources:

- MOTO Moscow Russia

- Mr. Leonid Zyakin

- Auto-Moto-Art

- Robbie Shergold (Chunk)

- B-Cozz archives

Pingback: Tula motoroller history (Video) - B-Cozz